On the 10th, at the helicopter facility of Korea Aerospace Industries (KAI) in Sacheon, Gyeongnam, Baek Seung-cheol, Senior Researcher of the Helicopter System Analysis Team (left), and Park Yeon-soo, Executive Director of the Power Transmission System Office, pose next to the Marine Corps 'Amphibious Attack Helicopter' based on the Surion. Provided by Korea Aerospace Industries

On the 10th, at the helicopter facility of Korea Aerospace Industries (KAI) in Sacheon, Gyeongnam, two helicopters were undergoing final inspections before delivery. The helicopters being inspected on this day are the last deliveries of the year heading to the Gyeongnam and Gangwon Police Aviation Units, and once delivered, the total number of Surions owned by the police will increase to 14. KAI has contracted to deliver a total of 39 Surions for official use to the police, the Korea Forest Service, and the National Fire Agency.

The rotary wing facility located right next to the helicopter facility is a space where helicopter assembly takes place, measuring 155 meters in length and 140 meters in width. Since the military helicopter Surion was first introduced in 2012, demand has increased even in the civilian market, leading to an expansion of production facilities in 2019. In December of last year, two units were exported to Iraq for KRW 135.8 billion, marking the beginning of its entry into the overseas market.

● 'Surion' Expands into Civilian Market with Technological IndependenceThe expansion of Surion into the civilian market was supported by technological independence. During the development process of Surion, KAI independently secured the core technologies for helicopter manufacturing, achieving a localization rate of approximately 65%. They succeeded in developing the blade, one of the three core technologies of helicopters along with the gearbox (power transmission device) and the automatic flight control system (AFCS).

When Surion was co-developed with Airbus Helicopters of France from 2006 to 2009, Airbus was cautious about transferring blade technology. The blades, which enable helicopters to fly, are made from advanced composite materials like carbon fiber, requiring highly complex technology. Baek Seung-cheol, Senior Researcher at KAI's Helicopter System Analysis Team, and about 10 other developers embarked on 'reverse engineering' by cutting the blades into 100 cross-sections and verifying each one. Baek recalled, "We poured our souls into developing the core helicopter technology with the determination to do it ourselves."

KAI is now pursuing the localization of helicopter power transmission systems, including gearboxes. The goal is to independently develop these by the early 2030s, becoming the sixth country in the world to possess such technology, following the United States, Germany, France, the United Kingdom, and Italy. Park Yeon-soo, Executive Director of KAI's Power Transmission System Office, stated, "We will achieve complete technological independence."

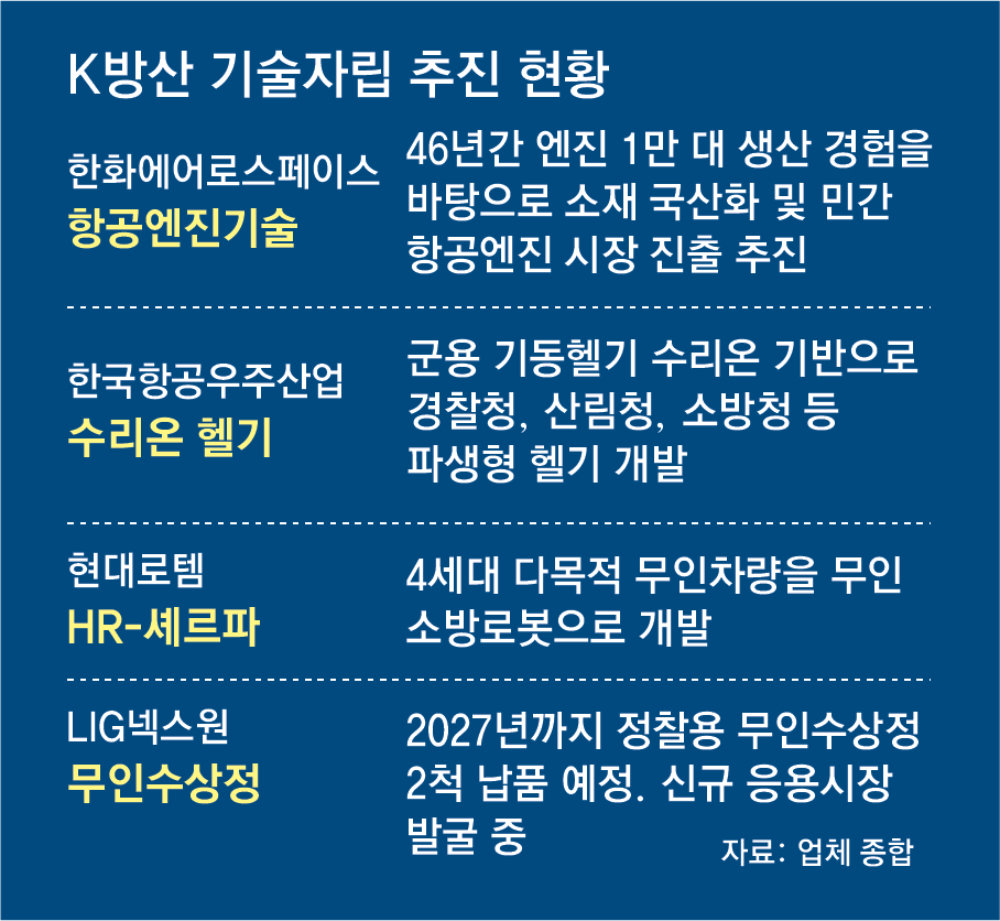

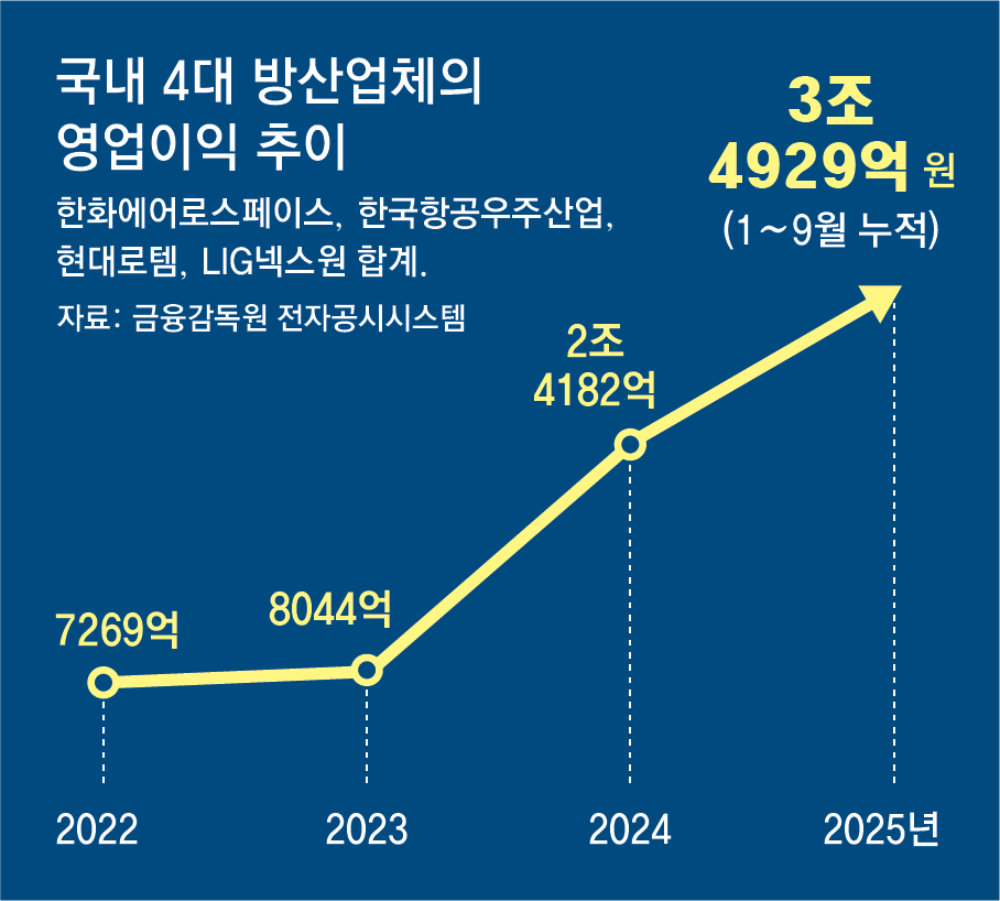

● Evolving K-Unmanned Systems, Developing Aviation EnginesWhile Surion has pioneered the skies, unmanned systems are opening new breakthroughs on land and sea. Hyundai Rotem is developing an unmanned firefighting robot specialized for fire suppression based on the fourth-generation multipurpose unmanned vehicle 'HR-Sherpa', which the National Fire Agency is preparing to deploy on-site starting this month. LIG Nex1's 'Sea Sword' unmanned surface vessel has been accumulating independent technology since 2015 and signed a contract worth KRW 39.9 billion with the Defense Acquisition Program Administration in December 2024. It plans to deliver two reconnaissance unmanned surface vessels by 2027, attracting attention for its potential use in various civilian fields such as marine environment monitoring and maritime rescue.

Hanwha Aerospace is challenging the development of aviation engines, considered the 'pinnacle' of aviation technology. The government plans to invest KRW 3.35 trillion over 14 years starting in 2027 to develop a 24,000-pound-class advanced aviation engine using purely domestic technology. Currently, they are developing turboshaft and turbofan engines for unmanned aerial vehicles, and if successful, an economic ripple effect of KRW 100 trillion is expected.

As defense technology independence leads to the revitalization of the civilian economy, Korea is advancing beyond being an 'arms exporting country' to becoming a 'defense technology powerhouse'. Jang Won-jun, a professor at Jeonbuk National University's Department of Advanced Defense Industry, emphasized, "Without technological independence, it is impossible to foster or export a leading defense industry," and added, "We must accelerate the development of advanced technologies such as artificial intelligence (AI) and drones."

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News