AgTech

AIMB Lab Drives Livestock Digital Shift with Innovation

Dong-A Ilbo |

Updated 2025.08.21

In the agricultural sector, smart farm technology is spreading, but it is mostly concentrated on facility horticulture or open-field crops. Livestock farming has relatively been in the blind spot of digital innovation. Particularly, the feed management sector, which is the first stage of the livestock value chain, has been an area where technology application has been minimal.

Aimbeelab (CEO Ko Byung-soo) is a startup established in 2020 to solve this problem. It has developed the feed bin management system 'MyFeed' to lead the digital transformation of the livestock industry. Particularly impressive is its active acceptance of customer feedback to continuously improve technology even after product launch. The reporters met CEO Ko Byung-soo at the Aimbeelab office to hear their innovation story.

- What motivated you to start a business in the livestock sector? Is there any special meaning behind the company name Aimbeelab?

: As a former army major, I have watched the difficulties in this field since my family is in the livestock business. The more I worked, the more I felt the need for the application of technology and information. Aimbeelab was established in 2020, and it is a company that contemplates how to connect livestock feed data, which no one has paid attention to, to the world.

The name Aimbeelab contains several meanings. It signifies adhering to basics like the alphabets A and B, emphasizes voluntary goal setting and realization as 'AIM BECOMES,' pursues high ideals as a variation of 'Ambitious,' and includes the meaning of researching sustainable growth as a 'LAB.'

- Is there a particular reason for focusing on the feed management sector within the livestock industry?

: When talking about the Fourth Industrial Revolution or digital transformation, it is easy to think of it as something happening in offices. However, applying innovation to primary industries is really important. Most primary industries focus on facility horticulture or open-field crops, but livestock farming is even more neglected.

Livestock farming deals with living animals and produces manure, so it inevitably has to be away from urban infrastructure. Therefore, it is a field that requires more application of technology and information. The livestock value chain involves raising, processing, and distributing, and the most frontline and repetitive task in this process is the procurement and management of feed.

There are about 70 startups related to livestock in Korea, but most focus on breeding and distribution. In contrast, we focused on this outdated feed management sector, believing that if it is innovated, it will affect the entire value chain of breeding, processing, and distribution. Among them, we particularly focused on the feed bin.

A feed bin is a large storage facility for livestock feed at farms. It is usually cylindrical or rectangular and can be several meters high. Farms store feed in these bins in bulk and dispense it to livestock as needed. The problem is that feed bins are so large and tall that it is difficult to visually check how much feed is left or its condition. We introduced the 'MyFeed' platform to improve these issues.

- What are the main features of MyFeed and what differentiates it from existing products?

: Our MyFeed consists of a palm-sized IoT device attached to the feed bin and web/app software to manage it. The basic principle is simple. When the device is attached to the lid of the feed bin, the LiDAR sensor measures the interior to determine the remaining feed, and the temperature and humidity sensors monitor the storage environment. This data is transmitted to the server via LTE communication, allowing farms or feed suppliers to check it in real-time via smartphone and web.

Existing products directly weighed or scanned the feed surface. These products required electrical connections and construction, making them expensive and cumbersome to install. We chose a method that predicts and corrects the remaining amount through AI and IoT technology.

Equipped with LiDAR and temperature and humidity sensors, and with built-in LTE functionality, no repeater, gateway, or communication line is needed. The ease of installation and management is very high.

The accuracy is about plus or minus 5%, and especially at the time of cattle feed intake, 99% accuracy can be expected. What we pursue is not simply measuring weight or other states. Rather, it is important to understand the usage trends and replacement cycles of the feed bin. We focused on building the infrastructure for this.

MyFeed's biggest differentiator is its low price and simple configuration. Startups need disruptive innovation. If existing products had 30 components, we simplify it to 10. It must be lighter, simpler, and more innovative. The price is about one-tenth of existing load cell-based products.

- How has the product evolved since its first launch in 2022? It seems continuous improvements are being made.

: We are not stopping after launching but continuously evolving. The first market launch was in 2022. At that time, it was a battery-operated product with a battery life of about three years. However, customers requested more convenience.

We told the installed farms that they could go up once every six months to clean and change the battery like a TV remote control, but even that was difficult for them. Listening to such customer voices, we thought it should be hassle-free once installed.

So, in July 2024, we launched a solar charging product. The solar product also added a wiper function to automatically solve the problem of dust accumulating on the sensor. A sensor to detect the opening and closing of the bin lid was also added. We continuously improved the communication method. Initially, we considered the LoRa method, a type of low-power communication technology, but it required a repeater or wiring. So, we discarded it during the development stage and switched to LTE. LTE uses a lot of battery, but it doesn't operate continuously for 24 hours; it measures only at suitable intervals for each feed bin to minimize battery consumption.

- Please explain in more detail the process of incorporating customer feedback into the product.

: Our team has all experienced working in the livestock industry. Some members joined after hearing about the problems in livestock from their parents and wanting to solve them. Knowing the field, we know what is truly needed. We actively accept customer feedback.

For example, the wiper function was created because customers said, "It's hard to go up and clean every six months because dust keeps accumulating." The lid opening sensor also came from the request, "I want to check if the lid is open."

We are developing technology not for the sake of technology but to solve field problems. That's why new ideas keep coming out.

- Software functions must also be important, not just hardware. What functions do you provide through the web and app?

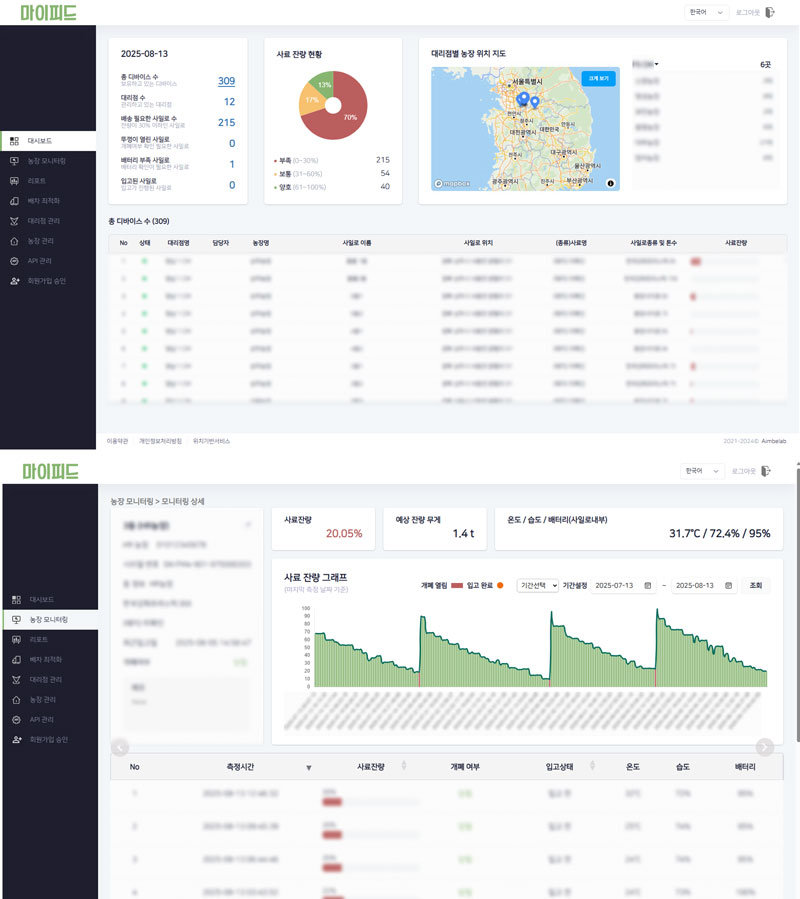

: We are continuously improving the software as well. Customers can check feed remaining, estimated weight, internal temperature and humidity, intake frequency, and consumption cycles through the web and mobile app.

Especially during feed replenishment, there are times when the lid is not properly closed or opened by the wind, and this is also notified in real-time. All these functions are continuously added according to customer demands.

There are cases where feed is added even though it is still full. This can cause the feed to harden due to not following the first-in, first-out principle. We are solving these realistic problems one by one. Currently, there are customers managing over hundreds of feed bins with our solution.

- How is the main customer base composed? It seems to target both farms and feed suppliers.

: Both feed companies and farms are our customers. Feed suppliers often install it for their customer farms. Previously, feed suppliers had to contact farms every morning to inquire about feed levels. Asking, "How empty is it?" was what agencies did when they came to work in the morning. But with the introduction of MyFeed, that is no longer necessary. It is convenient for both farms and feed suppliers, a 'win-win.'

- You give the impression of a continuously evolving company. What new features are you planning to develop?

: We do not stop. In the third quarter, we plan to release a product equipped with an image sensor. It will allow viewing the inside of the feed bin with photos to check for spoilage or stacking conditions. It is also being pursued as a project under the Ministry of SMEs and Startups R&D.

Additionally, we are preparing completely new content called smart feed bins. Existing feed bins only had storage functions, but smart feed bins integrated with our devices will have measurement and management functions as well. We are currently proceeding with collaboration contracts with leading domestic feed bin manufacturers, and actual products will be available in the third to fourth quarter of this year.

Our philosophy is not to make a product once and sell it as is, but to continuously upgrade and release new versions. Technology continues to evolve, and customer demands continue to change, so we must continue to evolve as well.

- I heard you are using the support program from the Korea Agriculture Technology Promotion Agency. How helpful has it been?

: We have received a lot of help since the Korea Agriculture Technology Promotion Agency was the Agricultural Technology Commercialization Foundation. We participated in the agri-food venture nurturing project and received help in creating prototypes, allowing us to enter the market stably.

Currently, we are receiving advanced technology support in the agri-food venture nurturing project, receiving support in various fields such as prototype development support, promotional marketing support, and new employment creation support. We are also receiving support for global expansion beyond domestic through the global acceleration program.

I especially recommend it to those who want to start a business in the primary industry. It is also very helpful in forming networks, such as linking with the livestock department in the Iksan region.

- I heard you have also started overseas expansion. What is the current situation and how is the response in the global market?

: We are actively expanding overseas, exporting products to Malaysia in 2024. The Korea Agriculture Technology Promotion Agency is also supporting this achievement to expand further through connections with local accelerators. We are at a stage where we are securing partners as active proposals are coming in from overseas.

- Lastly, please share your future plans and aspirations. What changes do you want to bring to the livestock industry?

: Through the development of smart feed bins, we want to expand initial achievements and actively support the improvement of work processes for domestic livestock practitioners. Although it is a primary industry, or rather because it is a primary industry, we believe that such technology and information are even more necessary.

We are not saying we will change everything ourselves. We aim to support livestock practitioners in improving their work processes. They have their style, and we are here to support it.

Above all, we want to be a continuously evolving company. Our reason for existence is to constantly improve and introduce new technologies to provide better value to customers, not to settle with a product once made. We will continue to be a reliable partner for livestock practitioners through continuous technology development and product improvement.

IT Donga Reporter Kim Young-woo (pengo@itdonga.com)

Ko Byung-soo, CEO of Aimbeelab / Source=Aimbeelab

Aimbeelab (CEO Ko Byung-soo) is a startup established in 2020 to solve this problem. It has developed the feed bin management system 'MyFeed' to lead the digital transformation of the livestock industry. Particularly impressive is its active acceptance of customer feedback to continuously improve technology even after product launch. The reporters met CEO Ko Byung-soo at the Aimbeelab office to hear their innovation story.

- What motivated you to start a business in the livestock sector? Is there any special meaning behind the company name Aimbeelab?

: As a former army major, I have watched the difficulties in this field since my family is in the livestock business. The more I worked, the more I felt the need for the application of technology and information. Aimbeelab was established in 2020, and it is a company that contemplates how to connect livestock feed data, which no one has paid attention to, to the world.

The name Aimbeelab contains several meanings. It signifies adhering to basics like the alphabets A and B, emphasizes voluntary goal setting and realization as 'AIM BECOMES,' pursues high ideals as a variation of 'Ambitious,' and includes the meaning of researching sustainable growth as a 'LAB.'

- Is there a particular reason for focusing on the feed management sector within the livestock industry?

: When talking about the Fourth Industrial Revolution or digital transformation, it is easy to think of it as something happening in offices. However, applying innovation to primary industries is really important. Most primary industries focus on facility horticulture or open-field crops, but livestock farming is even more neglected.

Livestock farming deals with living animals and produces manure, so it inevitably has to be away from urban infrastructure. Therefore, it is a field that requires more application of technology and information. The livestock value chain involves raising, processing, and distributing, and the most frontline and repetitive task in this process is the procurement and management of feed.

There are about 70 startups related to livestock in Korea, but most focus on breeding and distribution. In contrast, we focused on this outdated feed management sector, believing that if it is innovated, it will affect the entire value chain of breeding, processing, and distribution. Among them, we particularly focused on the feed bin.

A feed bin is a large storage facility for livestock feed at farms. It is usually cylindrical or rectangular and can be several meters high. Farms store feed in these bins in bulk and dispense it to livestock as needed. The problem is that feed bins are so large and tall that it is difficult to visually check how much feed is left or its condition. We introduced the 'MyFeed' platform to improve these issues.

CEO Ko Byung-soo introducing the feed bin management system of the MyFeed platform / Source=Aimbeelab

- What are the main features of MyFeed and what differentiates it from existing products?

: Our MyFeed consists of a palm-sized IoT device attached to the feed bin and web/app software to manage it. The basic principle is simple. When the device is attached to the lid of the feed bin, the LiDAR sensor measures the interior to determine the remaining feed, and the temperature and humidity sensors monitor the storage environment. This data is transmitted to the server via LTE communication, allowing farms or feed suppliers to check it in real-time via smartphone and web.

Existing products directly weighed or scanned the feed surface. These products required electrical connections and construction, making them expensive and cumbersome to install. We chose a method that predicts and corrects the remaining amount through AI and IoT technology.

Equipped with LiDAR and temperature and humidity sensors, and with built-in LTE functionality, no repeater, gateway, or communication line is needed. The ease of installation and management is very high.

The accuracy is about plus or minus 5%, and especially at the time of cattle feed intake, 99% accuracy can be expected. What we pursue is not simply measuring weight or other states. Rather, it is important to understand the usage trends and replacement cycles of the feed bin. We focused on building the infrastructure for this.

MyFeed's biggest differentiator is its low price and simple configuration. Startups need disruptive innovation. If existing products had 30 components, we simplify it to 10. It must be lighter, simpler, and more innovative. The price is about one-tenth of existing load cell-based products.

- How has the product evolved since its first launch in 2022? It seems continuous improvements are being made.

: We are not stopping after launching but continuously evolving. The first market launch was in 2022. At that time, it was a battery-operated product with a battery life of about three years. However, customers requested more convenience.

We told the installed farms that they could go up once every six months to clean and change the battery like a TV remote control, but even that was difficult for them. Listening to such customer voices, we thought it should be hassle-free once installed.

Installing a solar charging system on a customer's feed bin / Source=Aimbeelab

So, in July 2024, we launched a solar charging product. The solar product also added a wiper function to automatically solve the problem of dust accumulating on the sensor. A sensor to detect the opening and closing of the bin lid was also added. We continuously improved the communication method. Initially, we considered the LoRa method, a type of low-power communication technology, but it required a repeater or wiring. So, we discarded it during the development stage and switched to LTE. LTE uses a lot of battery, but it doesn't operate continuously for 24 hours; it measures only at suitable intervals for each feed bin to minimize battery consumption.

- Please explain in more detail the process of incorporating customer feedback into the product.

: Our team has all experienced working in the livestock industry. Some members joined after hearing about the problems in livestock from their parents and wanting to solve them. Knowing the field, we know what is truly needed. We actively accept customer feedback.

For example, the wiper function was created because customers said, "It's hard to go up and clean every six months because dust keeps accumulating." The lid opening sensor also came from the request, "I want to check if the lid is open."

We are developing technology not for the sake of technology but to solve field problems. That's why new ideas keep coming out.

- Software functions must also be important, not just hardware. What functions do you provide through the web and app?

: We are continuously improving the software as well. Customers can check feed remaining, estimated weight, internal temperature and humidity, intake frequency, and consumption cycles through the web and mobile app.

Especially during feed replenishment, there are times when the lid is not properly closed or opened by the wind, and this is also notified in real-time. All these functions are continuously added according to customer demands.

Monitoring multiple feed bins at a glance through MyFeed software / Source=Aimbeelab

There are cases where feed is added even though it is still full. This can cause the feed to harden due to not following the first-in, first-out principle. We are solving these realistic problems one by one. Currently, there are customers managing over hundreds of feed bins with our solution.

- How is the main customer base composed? It seems to target both farms and feed suppliers.

: Both feed companies and farms are our customers. Feed suppliers often install it for their customer farms. Previously, feed suppliers had to contact farms every morning to inquire about feed levels. Asking, "How empty is it?" was what agencies did when they came to work in the morning. But with the introduction of MyFeed, that is no longer necessary. It is convenient for both farms and feed suppliers, a 'win-win.'

- You give the impression of a continuously evolving company. What new features are you planning to develop?

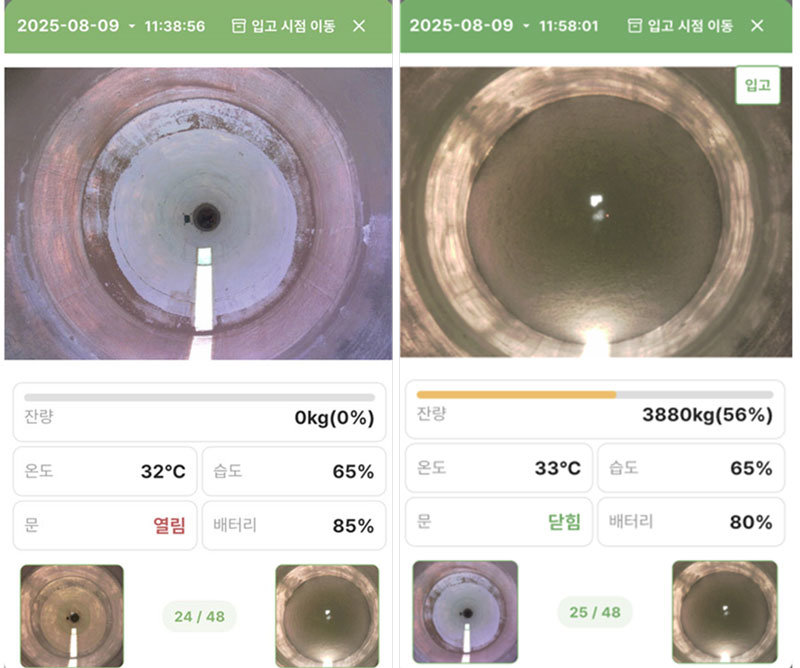

: We do not stop. In the third quarter, we plan to release a product equipped with an image sensor. It will allow viewing the inside of the feed bin with photos to check for spoilage or stacking conditions. It is also being pursued as a project under the Ministry of SMEs and Startups R&D.

Example of feed bin image display function to be added to future products / Source=Aimbeelab

Additionally, we are preparing completely new content called smart feed bins. Existing feed bins only had storage functions, but smart feed bins integrated with our devices will have measurement and management functions as well. We are currently proceeding with collaboration contracts with leading domestic feed bin manufacturers, and actual products will be available in the third to fourth quarter of this year.

Our philosophy is not to make a product once and sell it as is, but to continuously upgrade and release new versions. Technology continues to evolve, and customer demands continue to change, so we must continue to evolve as well.

- I heard you are using the support program from the Korea Agriculture Technology Promotion Agency. How helpful has it been?

: We have received a lot of help since the Korea Agriculture Technology Promotion Agency was the Agricultural Technology Commercialization Foundation. We participated in the agri-food venture nurturing project and received help in creating prototypes, allowing us to enter the market stably.

Currently, we are receiving advanced technology support in the agri-food venture nurturing project, receiving support in various fields such as prototype development support, promotional marketing support, and new employment creation support. We are also receiving support for global expansion beyond domestic through the global acceleration program.

I especially recommend it to those who want to start a business in the primary industry. It is also very helpful in forming networks, such as linking with the livestock department in the Iksan region.

- I heard you have also started overseas expansion. What is the current situation and how is the response in the global market?

: We are actively expanding overseas, exporting products to Malaysia in 2024. The Korea Agriculture Technology Promotion Agency is also supporting this achievement to expand further through connections with local accelerators. We are at a stage where we are securing partners as active proposals are coming in from overseas.

- Lastly, please share your future plans and aspirations. What changes do you want to bring to the livestock industry?

: Through the development of smart feed bins, we want to expand initial achievements and actively support the improvement of work processes for domestic livestock practitioners. Although it is a primary industry, or rather because it is a primary industry, we believe that such technology and information are even more necessary.

We are not saying we will change everything ourselves. We aim to support livestock practitioners in improving their work processes. They have their style, and we are here to support it.

Above all, we want to be a continuously evolving company. Our reason for existence is to constantly improve and introduce new technologies to provide better value to customers, not to settle with a product once made. We will continue to be a reliable partner for livestock practitioners through continuous technology development and product improvement.

IT Donga Reporter Kim Young-woo (pengo@itdonga.com)

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News