AI Robotics

‘AI Plant Chief’ to Oversee Chip Design, Production

Dong-A Ilbo |

Updated 2026.02.09

[AI Robots Transforming K-Manufacturing] 〈6〉 SK Arms Itself with AI Data

Yongin Fab 1 Targets ‘Fully Autonomous Operation’ Next Year… Entire Process to Be Run Automatically by AI Without Human Intervention

Veteran Employees’ Skills Converted into AI Data… Preventing ‘Skill Gaps’ from Aging and Retirement

Yongin Fab 1 Targets ‘Fully Autonomous Operation’ Next Year… Entire Process to Be Run Automatically by AI Without Human Intervention

Veteran Employees’ Skills Converted into AI Data… Preventing ‘Skill Gaps’ from Aging and Retirement

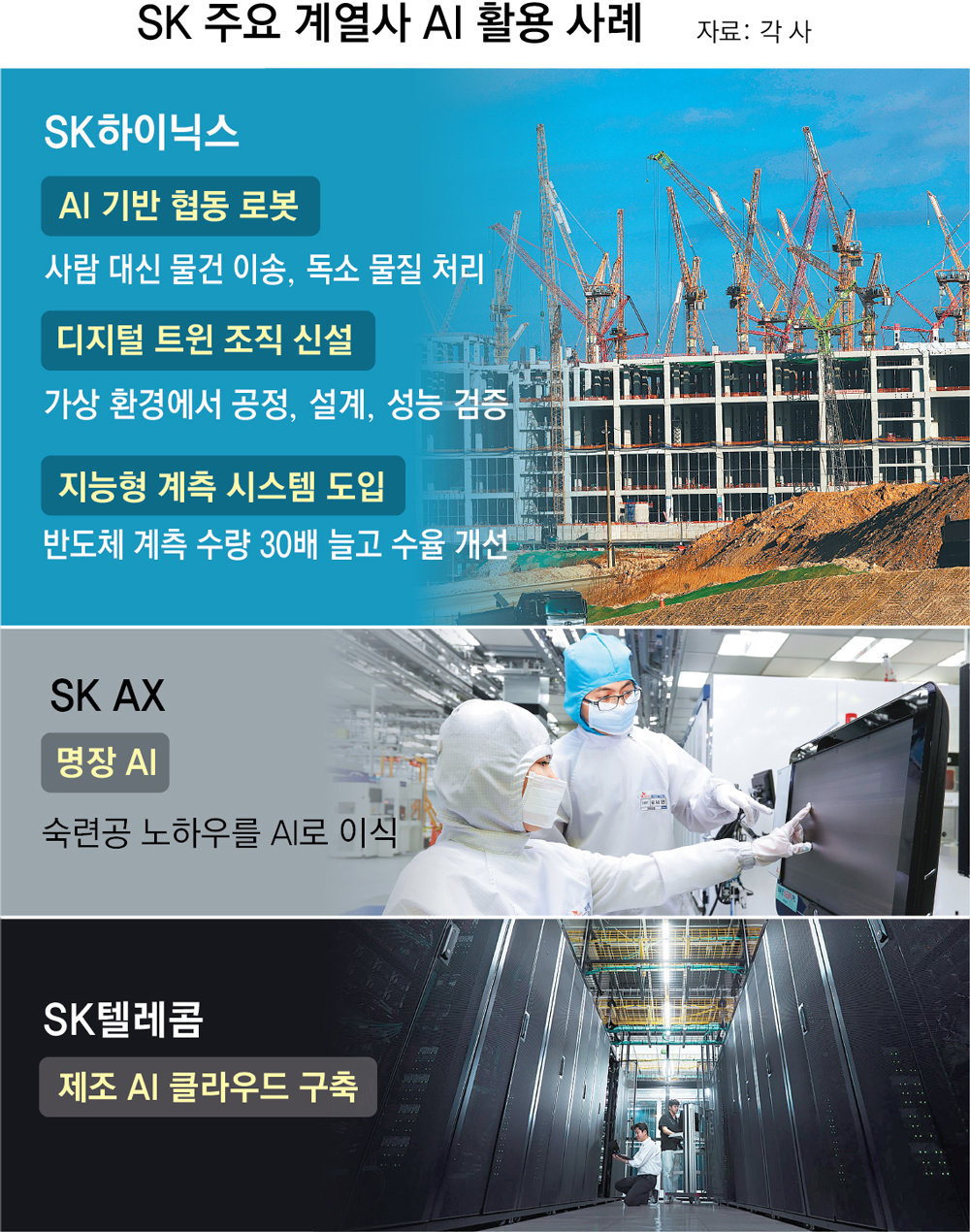

Yongin Fab 1 is scheduled to debut in 2027 as SK hynix’s first “fully autonomous fab.” The goal is to build a semiconductor “autonomous operating fab” in which artificial intelligence (AI) performs all operations automatically without human intervention. In effect, AI will serve as the “plant manager” of an advanced semiconductor fab.

To this end, SK hynix is currently accumulating AI data at its existing fabs. An SK hynix official said, “From semiconductor fabs and design to sales, every space is a source of AI data.”

SK is also pushing ahead with its “Master Artisan AI” project, in which the know-how of experienced veteran employees at key manufacturing affiliates’ sites is converted into data for AI to learn from. The group is drawing up a blueprint to spread AI data-based manufacturing innovation across all its affiliates.

● Every space in the semiconductor plant is a source of AI data

However, at Yongin Fab 1, which is scheduled to begin operation next year, AI will be involved in every moment of fab operation. Operational AI will automate real-time decision-making, and “digital twin” technology will be introduced to virtually simulate the plant and then apply the optimal operating methods derived from the simulation to the actual site. Physical AI, in which equipment and robots control themselves, will also be applied. Data is the foundation of an autonomous fab where AI controls the plant.

AI data also serves as the basis for helping new engineers in the semiconductor research and development (R&D) division quickly adapt to their work. The “in-house customized AI assistant” operated by SK hynix is built on the experiences of senior semiconductor engineers and a vast trove of past technical documents, process recipes, and troubleshooting manuals. New engineers solve problems by querying an AI system that aggregates the know-how of their seniors.

In addition, SK hynix has introduced an “intelligent metrology system” in which AI autonomously determines which parts require measurement based on accumulated R&D data, skipping measurements for unnecessary processes. By focusing limited equipment only on what truly needs to be inspected, metrology throughput has increased 30-fold and yield has improved. Verifying more data through AI at the R&D stage enables the company to finalize optimal process recipes more quickly and to raise initial yields faster when mass production begins in earnest.

On 3 November last year, at the “SK AI Summit 2025” exhibition held at COEX in Gangnam District, Seoul, a robot inspects semiconductor wafers for defects. Dong-A Ilbo DB

In fact, AI data has recently been playing a key role in boosting productivity and yield at semiconductor manufacturing sites. AI analyzes real-time data pouring in from sensors attached to equipment and, based on this, stops equipment operation or takes immediate corrective action. In hazardous processes such as moving heavy objects or handling toxic substances inside the fab, AI-based collaborative robots work in place of humans. According to SK hynix, the introduction of such systems has reduced similar types of accidents by 75%.

● Spreading expert know-how across all affiliates with “Master Artisan AI”

SK Group plans to drive manufacturing innovation across the group based on AI data by utilizing “Master Artisan AI,” planned by SK AX (formerly SK C&C). Master Artisan AI has been applied to the processes and operations of actual manufacturing, facilities, and plant operations at various SK Group affiliates in sectors such as energy, chemicals, shipbuilding, and secondary batteries, and is currently in the verification stage.

Master Artisan AI uses AI to prevent a “skills gap” arising from an aging workforce and the retirement of veteran personnel. Instead of having skilled workers draft separate documents to transfer their techniques, the system collects their know-how based on data generated naturally as they work.

It accumulates records of data collected from sensors attached to equipment, alarm histories, and the decisions skilled workers make in specific situations. An SK AX official explained, “In the same situation, there are times when production is halted and times when it is only monitored,” adding, “Based on this, the system determines the range of normal conditions.” The company plans to embed such know-how into AI agents so that anyone can use it in the future.

SK Telecom plans to build a “manufacturing AI cloud” by procuring about 2,000 RTX Pro 6000 graphics processing units (GPUs) from NVIDIA. SK Telecom CEO Jung Jae-heon said at the SK AI Summit 2025 held in November last year, “The manufacturing AI cloud is expected to be used for the AI transformation of major SK Group manufacturers, including SK hynix.”

Yongin=Lee Min-a

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News