Pharmaceutical R&D

Universal Blood Type Developed, Surpassing Donation Limits

Dong-A Ilbo |

Updated 2026.01.24

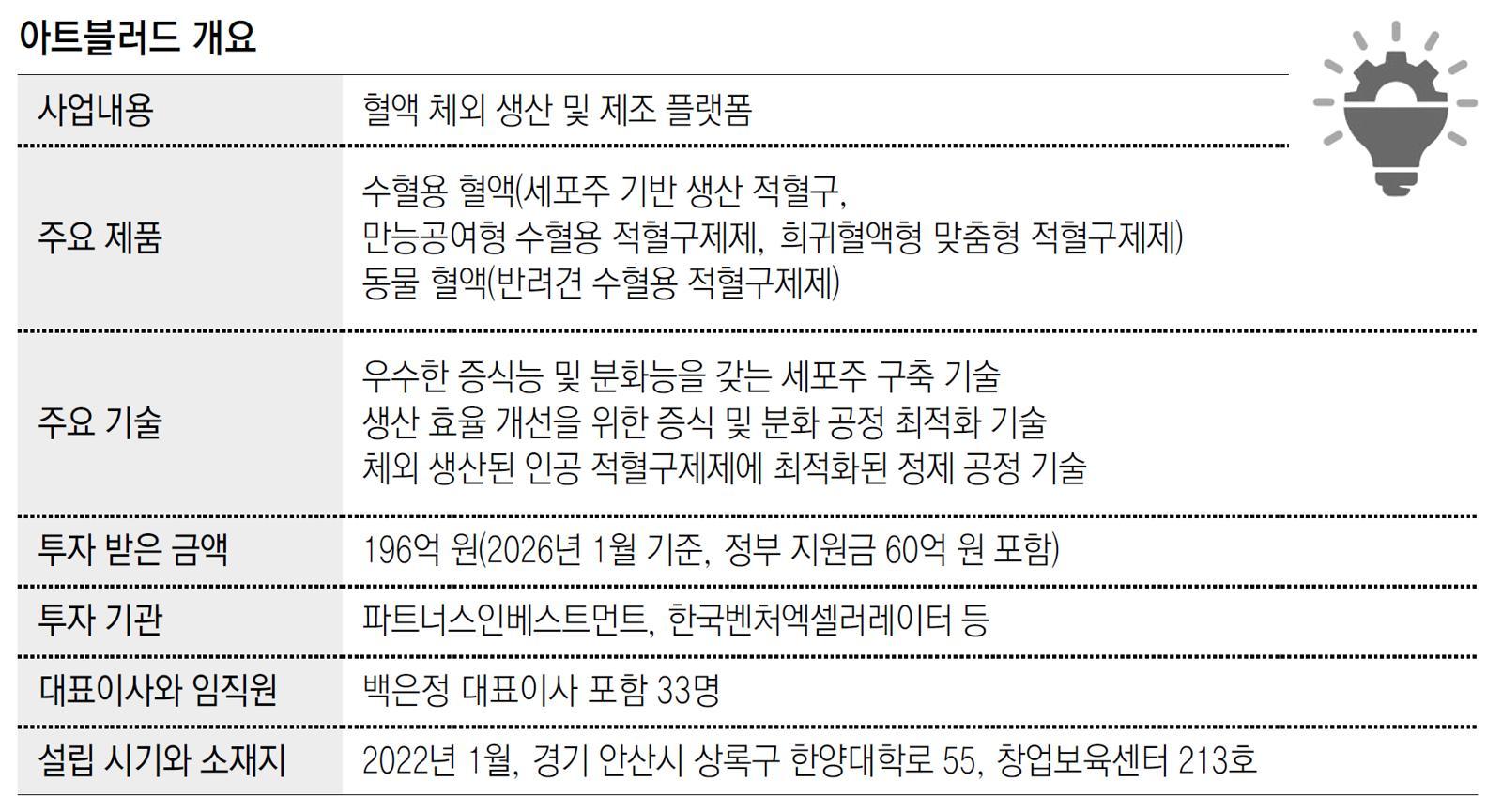

Artblood Pioneers the World’s First Artificial Blood

A devastating reality where surgeries are delayed for lack of blood… University hospital doctor who witnessed it for 20 years starts a company

With a shrinking population, blood donation alone can’t meet demand… Successfully manufactures cell line-based artificial red blood cells

The only one worldwide to do it with normal cells… No immunological side effects or risk of infection

A devastating reality where surgeries are delayed for lack of blood… University hospital doctor who witnessed it for 20 years starts a company

With a shrinking population, blood donation alone can’t meet demand… Successfully manufactures cell line-based artificial red blood cells

The only one worldwide to do it with normal cells… No immunological side effects or risk of infection

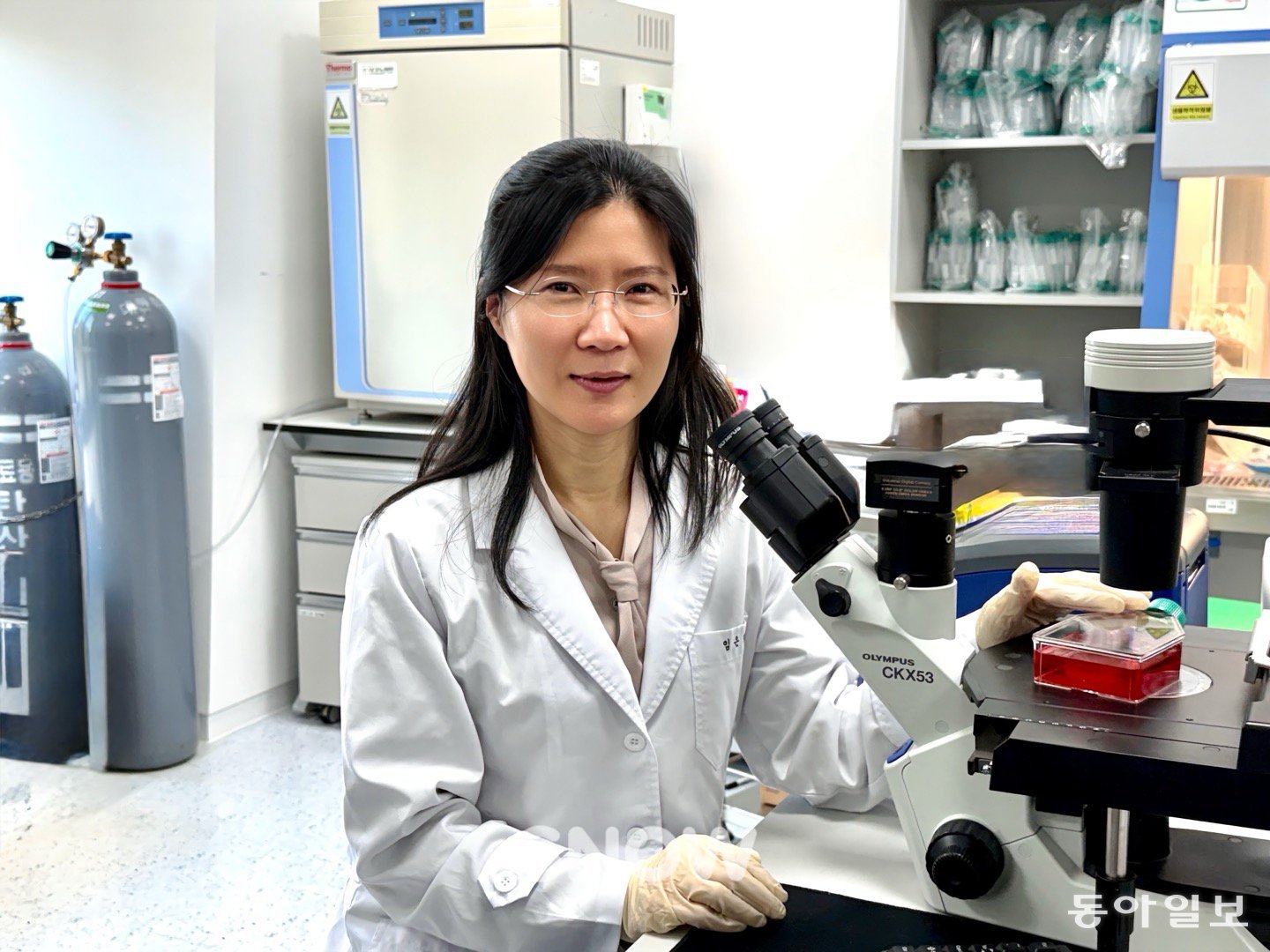

On January 13, Artblood CEO Baek Eun-jung (Professor of Laboratory Medicine at Hanyang University Hospital) points to a container filled with rapidly proliferating red blood cells at the company’s research institute in Seocho-gu, Seoul, explaining the technology for cell line-based artificial red blood cell production. Photo by reporter Heo Jin-seok, jameshur@donga.com

“There are not a few days when the hospital has only one pack of blood. If a surgical patient arrives on such a day, surgery is impossible.”Artblood CEO Baek Eun-jung (49) is a specialist in transfusion medicine and a professor in the Department of Laboratory Medicine at Hanyang University Hospital. The reality she witnesses every day in her 20th year as a university hospital physician is grim. Surgeries are postponed due to a shortage of blood for transfusion, and emergency patients from outside sometimes cannot be accepted. Surgeons at secondary hospitals desperately call, practically begging for blood. Because this would be illegal, it is impossible to share blood on an individual basis. In emergencies where the patient’s blood type cannot be identified, Rh-O, a universal donor blood type that does not trigger antigen-antibody reactions, must be used, but only 0.3% of the population in Korea has this blood type. The idea of maintaining sufficient universal donor blood is little more than a dream. The country’s average blood stock is 4.2 days, below the recommended level of 5 days. The number of blood donors continues to decline.

Meeting with this newspaper on January 13 at Artblood’s research institute in Seocho-gu, Seoul, Baek said, “Korea is the only country where, due to blood shortages, larger hospitals are legally required to establish a transfusion management office and assign dedicated staff,” adding, “Low birth rates are reducing the pool of potential donors, while population aging is causing transfusion demand to surge. This structural problem led us to pursue commercialization of artificial blood.”

● World-leading technology

Artblood’s core technology is the mass production of artificial red blood cells using cell lines. The key is to introduce specific genes into hematopoietic stem cells to create cell lines that can proliferate continuously. These cell lines proliferate over long periods, similar to hematopoietic stem cells in human bone marrow, and once established, can be used to continuously produce red blood cells in cell culture facilities.

Globally, only three entities are taking on this challenge: the UK’s Scarlett, the US’s SerPhil, and Korea’s Artblood. Among them, Artblood is the only one that has established red blood cell-producing cell lines with normal chromosomes. Scarlett uses cancer cell-based cell lines, which cannot be used for general transfusion, and SerPhil relies on induced pluripotent stem cells, which generate embryonic-type hemoglobin different from that in adults, resulting in reduced oxygen-carrying capacity.

Baek explained, “We enabled the continuous expression of genes involved in proliferation. At the erythroblast precursor stage, the cells can keep proliferating and can be induced to differentiate when desired. We are the only ones in the world who have achieved this using normal cells.”

Artblood’s 50L bioreactor. Red blood cells are produced inside the cylindrical device on the left. Source: Artblood

Artblood has successfully produced red blood cells in a 50L bioreactor. It has secured end-to-end process technology encompassing proliferation, differentiation, and purification. The red blood cells produced have the same biconcave shape as those derived from donated blood. The company plans to expand to a 150L scale this year and ultimately aims for mass production at the tens-of-thousands-of-liters level.The advantages of this technology are clear. It can be transfused regardless of blood type. There is no risk of infection as with donated blood. It is safe from both immunologic and non-immunologic adverse reactions. Another strength is that these red blood cells survive longer in vivo than those from donated blood.

Artblood is also developing red blood cells for companion dogs. In fact, to commercialize artificial blood for humans, a verification process similar to clinical trials is required, and animal blood is being used first to validate the technology. There is also the practical aim of addressing the reality that companion animal blood is even harder to obtain than human blood. Baek said, “If we can produce blood for dogs using our technology and perform transfusions safely, the likelihood that it can be applied safely to humans will increase.”

● Long preparation for start-up and obstacles

Baek’s research on artificial blood dates back to 2006. While working as a fellow in Professor Kim Hyun-wook’s laboratory in the Department of Laboratory Medicine at Yonsei University at the time, she encountered an innovative paper showing that red blood cells could be cultured ex vivo from hematopoietic stem cells. “It was an experiment that my predecessor had tried once and failed,” Baek recalled. “But I tried it again with the remaining reagents, and it turned out to be reproducible. That was the beginning.”

This was a completely new field with only two related papers in the world. Baek was recognized as a pioneer, becoming the first Korean to deliver a keynote speech at the International Society of Blood Transfusion. Over 20 years, she has published more than 40 papers in leading international journals and secured some 30 domestic and international patents.

However, success in the laboratory and actual blood production were on a different level. From 2013, Baek began preparing to start a company. She attended new drug development lectures wherever she could, as the advice from businesspeople she met was consistent: “A technology like this can never be realized unless it is commercialized.” For five years, she led a double life, working as a professor by day and attending start-up education programs at night.

A turning point came in 2021. In the government’s Innovative Growth Big 3 Promotion Meeting, it was decided that clinical-grade artificial blood production technology would be secured through a multi-ministry joint project. In 2023, Artblood became the main research team for a large-scale national R&D project in this area. “The government showed its commitment,” Baek said. “I felt we had to respond. There was no reason to hesitate.”

Unanticipated obstacles awaited after the company was founded. There was no animal model for non-clinical testing, because the product under development is blood. Since mice have different blood types from humans, human-type blood is immediately destroyed when administered to them. The non-clinical and clinical trial pathways themselves had to be established from scratch. The purification process was also far more difficult than expected. “The required technologies are all first-of-their-kind in the world, so efficiency improvements are needed at multiple stages. It is a highly challenging task,” Baek said.

Legally, blood is defined as blood cells and plasma collected from the human body, so existing regulations could not be applied to artificial blood. It was only in August 2025 that the Ministry of Food and Drug Safety classified artificial blood as an “advanced biopharmaceutical,” opening the way for clinical trials.

● Artificial blood that could mark a milestone in human history

In 2023, the government launched the “Cell-based Artificial Blood Technology Development Project Group,” involving the Ministry of Health and Welfare, the Ministry of Science and ICT, the Ministry of Trade, Industry and Energy, the Ministry of Food and Drug Safety, and the Korea Disease Control and Prevention Agency. This is the first phase of the project, with KRW 47.1 billion to be invested over five years. Artblood won the sole contract for the core task of mass-producing red blood cell preparations for human transfusion. In the same year, it also secured a project under the Fast Track Program for Commercializing Next-generation Promising Seed Technologies and succeeded in producing, for the first time in the world, red blood cells that can be transfused to dogs.

Artblood currently has 33 executives and employees (including 26 R&D staff) engaged in research and production. Experts from various fields have joined forces for this world-first endeavor. They include Chief Technology Officer for Bio (CTbO) Noh Kyung-hwan, formerly of Kangstem Biotech; Chief Technology Officer for Cell Line (CTcO) Kim Sun-kyu, formerly of Samsung Biologics; Chief Development Officer (CDO) Jung Young-mi, formerly of CJ Healthcare; and Chief Product Officer (CPO) Yoo Soo-hyun, formerly of LG Chem. The company has secured a factory site (GMP-certified facility) in Ansan, Gyeonggi Province, and is operating an affiliated research institute occupying the 6th and 7th floors of a building in Seocho-gu, Seoul.

In August last year, Artblood was selected as a portfolio company of the Youth Start-up Fund No. 3 in Ansan, Gyeonggi Province, and relocated its headquarters to Ansan. Source: Artblood

Artblood aims to begin clinical trials in 2029. In the short term, it plans to develop universal donor (Rh-O) red blood cells for transfusion; in the medium term, customized red blood cells for rare blood types and red blood cells for companion dogs; and in the long term, a drug delivery platform business.Artblood forecasts that the global transfusion blood market will grow from USD 37 billion (approximately KRW 47 trillion) in 2022 to USD 54.5 billion (approximately KRW 70 trillion) by 2030. The red blood cell preparation segment accounts for about 50% of the total. Baek hopes to resolve the global blood shortage through artificial blood technology and expects the market to form naturally.

“Imagine how beneficial it would be if universal donor blood could be kept on standby in emergency rooms,” Baek said. “Imagine if no surgery were delayed due to a lack of blood. For that day, we are taking one step forward at a time.”

Heo Jin-seok

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News