AI / POSCO

Workers Vanish as AI Takes Over Steel Blast Furnaces

Dong-A Ilbo |

Updated 2026.01.19

[AI Robots Transforming K-Manufacturing] 〈4〉 Molten ‘AI Steel’ Boiling at POSCO

Tasks Once Done by Workers in Heat-Resistant Suits Relying on “Feel”… Now Replaced by AI-Powered Sensors, Cameras, and Robots

Workers Only Monitor from Remote Offices

China and Japan Also Go All-In… “AI Steel” Race Heats Up

Tasks Once Done by Workers in Heat-Resistant Suits Relying on “Feel”… Now Replaced by AI-Powered Sensors, Cameras, and Robots

Workers Only Monitor from Remote Offices

China and Japan Also Go All-In… “AI Steel” Race Heats Up

At the hot metal preliminary treatment process of Steelmaking Plant 1 at POSCO Pohang Works, a robotic arm is removing impurities (slag) from boiling hot metal. This robotic arm uses artificial intelligence (AI) to analyze the brightness and texture of the hot metal with a special camera and precisely selects only the impurities. Provided by POSCO

On the afternoon of the 7th, at Steelmaking Plant 2 of POSCO Pohang Works in Pohang, North Gyeongsang Province. Inside, the heat was intense enough to make the sub-zero temperatures outside irrelevant. Every time an overhead crane moved a 300-ton ladle (transport vessel) of hot metal, a roar and a sense of pressure filled the air. Between them, three basic oxygen furnaces (BOFs) the height of a three-story apartment building stood in imposing form. The BOF is the heart of a steel mill, where oxygen is blown into hot metal to make steel.Until very recently, this was an “extreme workplace” where workers fought for their lives in front of hot metal over 1,600 degrees Celsius. Operators wearing heatproof suits watched the hot metal with the naked eye and manually tilted the BOF with a lever to tap the steel. If they missed the timing, the hot metal would be discarded or contaminated with impurities (slag). It was a perilous moment that relied on the “intuition” of veteran workers.

However, the scene in front of BOF No. 1 that day was completely different. Cameras and sensors had replaced people at the furnace, and operators were monitoring screens in an “integrated control room” located tens of meters away.

On the monitors, internal temperature, composition, and raw material quantities analyzed by artificial intelligence (AI) were displayed in real-time graphs. AI controls hundreds of variables, and operators only approve its decisions. When tapping began, AI analyzed the wavelength of the molten steel through a special camera. At the very moment impurities were about to flow out with the red-hot metal, AI stopped the tapping by bringing the BOF upright. It was a case of fully autonomous AI operation.

Noh Hee-woon, manager of the Technology Development Section in POSCO’s Steelmaking Department, said, “In the past, humans held the lever and wrestled with the heat, but now AI does the driving and humans supervise it, marking a paradigm shift,” adding, “In the case of BOF No. 1, AI controls the entire process from raw material charging and blowing (smelting) to tapping.”

● From “smart” to “intelligent”… the evolution of steel mills

In the process of turning hot metal into steel, steelmaking is considered the most demanding stage for achieving the target composition. POSCO has introduced the world’s first “intelligent factory” concept to this process. AI makes its own judgments and controls operations to carry out intelligent steelmaking.

POSCO Pohang Works has currently deployed AI autonomous operation systems in three core sections of Steelmaking Plants 2 and 3: hot metal preliminary treatment (KR), basic oxygen furnace (BOF), and secondary refining (RH).

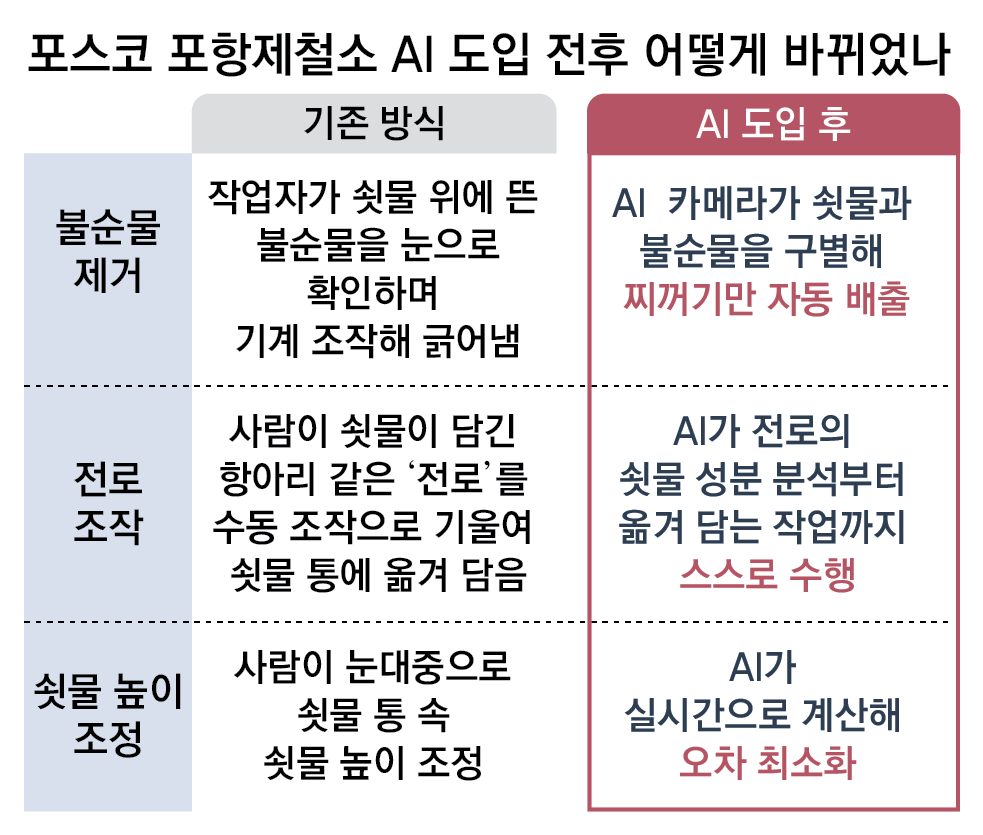

Changes are taking place from the initial stage of the process, the hot metal preliminary treatment. In the past, to remove slag floating on the boiling hot metal, workers had to stand near the molten bath, hold the robot arm controller, and operate it directly. Delicate manual skills, like skimming fat from a broth, were essential.

Since the introduction of vision AI at Steelmaking Plant 3 in May last year, however, robots independently find the optimal path to remove slag. When the high-temperature process is filmed with a special camera, AI analyzes brightness and texture to cleanly distinguish between hot metal and slag. AI calculates around 1,000 variables to eliminate quality variation, increasing yield by 1–2 percentage points and achieving an annual output gain of several hundred thousand tons.

The BOF process, the core of steelmaking, is a battle against complex variables. The amount of oxygen and auxiliary materials to be injected must change depending on the type of scrap and the temperature of the hot metal. To address this, POSCO has implemented a “no-touch operation” system. AI automatically calculates the optimal blend ratio in a single step based on a thermodynamic model.

AI also plays a crucial role in the secondary refining process. In this stage, hot metal is drawn up and circulated through an immersion tube, similar to a straw, and the major challenge has been that the molten steel level changes frequently depending on the vacuum conditions. In the past, operators adjusted the height of the ladle by rough estimation, but now AI precisely calculates the level and moves the ladle in fine increments to perform optimal refining. This has eliminated variations between operators and secured uniform quality.

● Silent “AI hot metal” war among Korea, China, and Japan

The adoption of AI in the steel industry is an essential strategy for survival. Under the triple pressures of rising costs, low growth, and carbon neutrality, competition from China and Japan is intensifying. China Baowu Steel Group is in the process of building a “manless steel mill” by introducing 10,000 AI robots by 2026, while Nippon Steel is investing JPY 100 billion (about KRW 933.5 billion) over five years to transfer the know-how of retiring skilled workers into AI. According to market research firm Technavio, competition is fierce, with more than 70% of leading steelmakers investing in digital solutions.

POSCO has gone beyond innovation in individual processes to stake its chances on “hyperconnectivity” that links them as one. The centerpiece is its proprietary integrated logistics control system “PTX.” Because hot metal continues to cool while being transported, reducing time directly leads to cost competitiveness. PTX predicts the entire process like a high-speed rail control system and optimizes routing, reducing waiting time between processes to nearly zero. McKinsey has analyzed that such digital transformation can increase productivity by up to 15%.

With this technology, POSCO plans to lead the future of manufacturing. The AI systems currently applied to parts of Steelmaking Plants 2 and 3 in Pohang will be expanded to all steelmaking plants at Pohang Works by 2027. The expected benefits, including cost reductions, amount to approximately KRW 39 billion per year.

Kim Yong-tae, leader of the Steelmaking Technology Section in POSCO’s Steelmaking Department, said, “With AI, it has become possible to use low-cost raw materials while still producing high-quality products, and the defect rate has decreased by nearly 70%,” adding, “By unmanning high-risk tasks, this is a ‘human-centered innovation’ that fundamentally prevents accidents and will serve as a control foundation for future processes such as hydrogen reduction steelmaking.”

Pohang=Kim Jae-hyeong Reporter monami@donga.com

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News