CES 2026

At CES, 3M Showcases Core Mobility Materials

Dong-A Ilbo |

Updated 2026.01.12

There were few exaggerated structures or eye‑catching decorations. Instead, a neat structure and restrained colors enveloped the entire space, creating a calm atmosphere. The 3M booth was easily recognizable even from a distance, not because of its size or splendor, but thanks to its composed impression and well‑balanced design.

Even in the middle of a busy aisle where visitors were constantly passing by, the 3M booth appeared oddly relaxed. While the surrounding booths competed for attention with sound and light, this space, with its understated ambience, instead caused people to pause their steps.

At the center of the booth, a white 2025 all‑new Lincoln Navigator was on display. In contrast to the strong red color of the booth, it naturally drew the gaze of visitors. The vehicle display served as a symbolic device to showcase 3M’s technological capabilities. Visitors on the day were able to directly experience a future vehicle environment incorporating 3M’s advanced materials technologies and digital solutions.

The vehicle is equipped with a 48‑inch panoramic display, featuring 3M’s Advanced Light Control Film (ALCF‑A5+) technology. This film is designed to concentrate light from the display toward the occupants and prevent it from being directed toward the windshield. As a result, it reduces reflections and visual distraction, providing a more intuitive and expansive interface experience. Seeing it in person, visitors could perceive this more intuitive and wide interface experience.

This display organically integrates automotive design vision, display engineering, and materials science, enabling safer and more flexible HMI (Human‑Machine Interface) integration. This achievement led to the 2025 SPE Automotive Innovation Award (Safety category), presenting a new standard for safety in automotive displays.

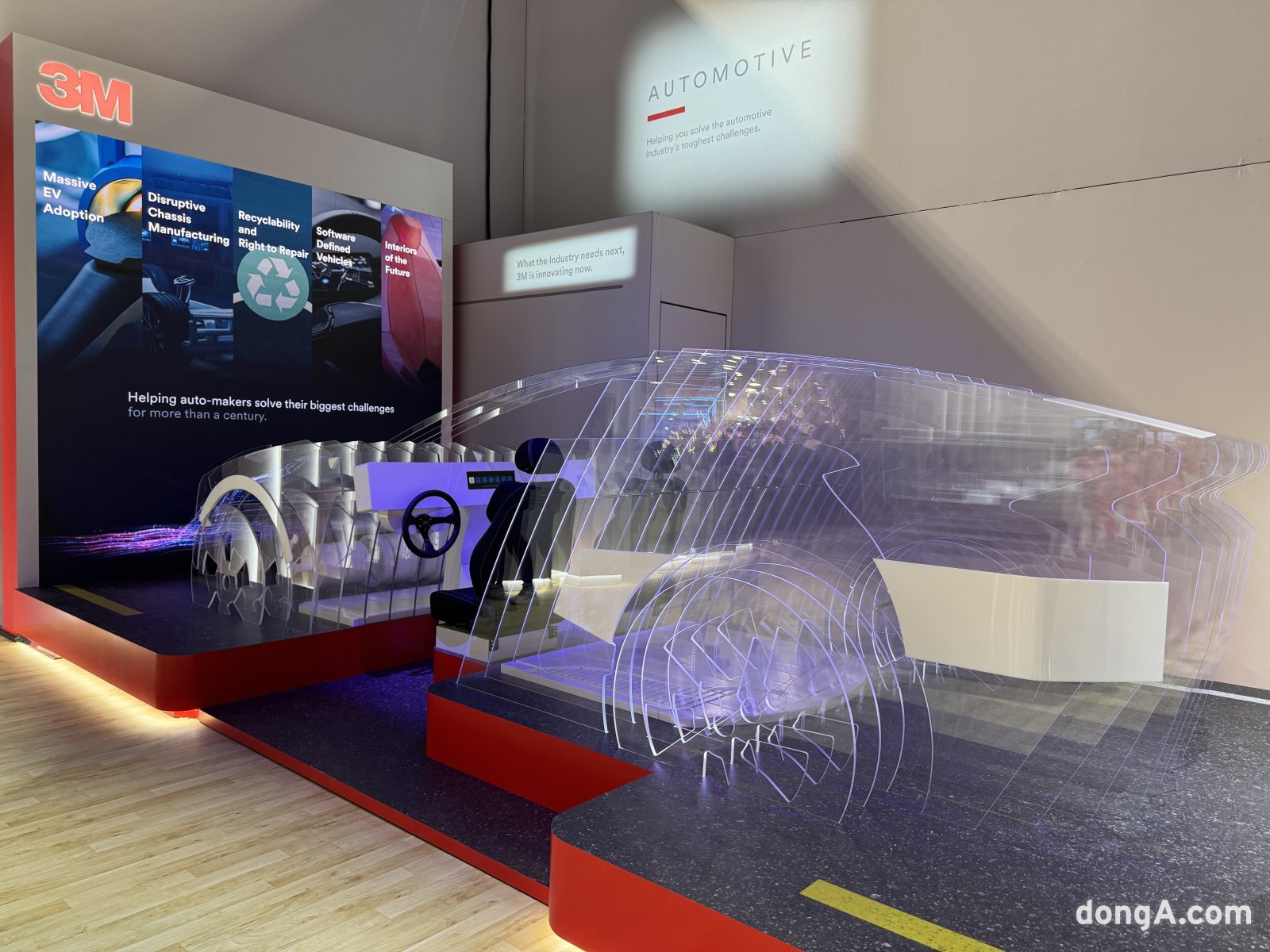

Inside a white curtain area, visitors could encounter 3M’s core technologies. At CES 2026, 3M focused on presenting major trends in the automotive industry along with its own materials and digital solutions. The latest 3M technologies were showcased across a wide range of fields, including electrification (EVs), software‑defined vehicles (SDVs), battery safety, and future‑oriented interiors.

Anja Walk, communications supervisor at 3M, met on site that day, said, “In the automotive industry, electrification and battery‑powered vehicles, innovations in chassis design and manufacturing, and changes in future‑oriented interiors are the key trends,” adding, “As vehicles transition to software‑defined vehicles, the importance of electronic devices and display technologies is increasing, and 3M is expanding the experience and materials technologies accumulated in the electronics industry into the automotive sector.” She continued, “3M is a company that supports the implementation of in‑vehicle software through hardware and materials.”

3M unveiled a variety of materials solutions designed to enhance the safety of electric vehicle batteries. Thermal stabilization materials and impact‑absorbing pads applied between battery cells are engineered to suppress the spread of heat to adjacent cells, even if a particular cell overheats. This helps prevent fire propagation and is designed to secure time for the driver to exit the vehicle. In addition, the company presented various battery assembly materials such as structural adhesives and tapes for battery box assembly, as well as special material solutions that can be applied inside the vehicle, comprehensively supporting safety‑oriented design for both batteries and vehicles.

On the same day, 3M introduced noise management and lightweight materials aimed at improving the in‑vehicle environment. Non‑sound‑absorbing materials that reduce road noise and glass bubbles for plastic lightweighting help enhance ride comfort while also contributing to improved fuel efficiency. In HMI areas such as displays and sensors, adhesive, EMI shielding, and vibration‑damping materials are applied to enable a more refined in‑cabin experience.

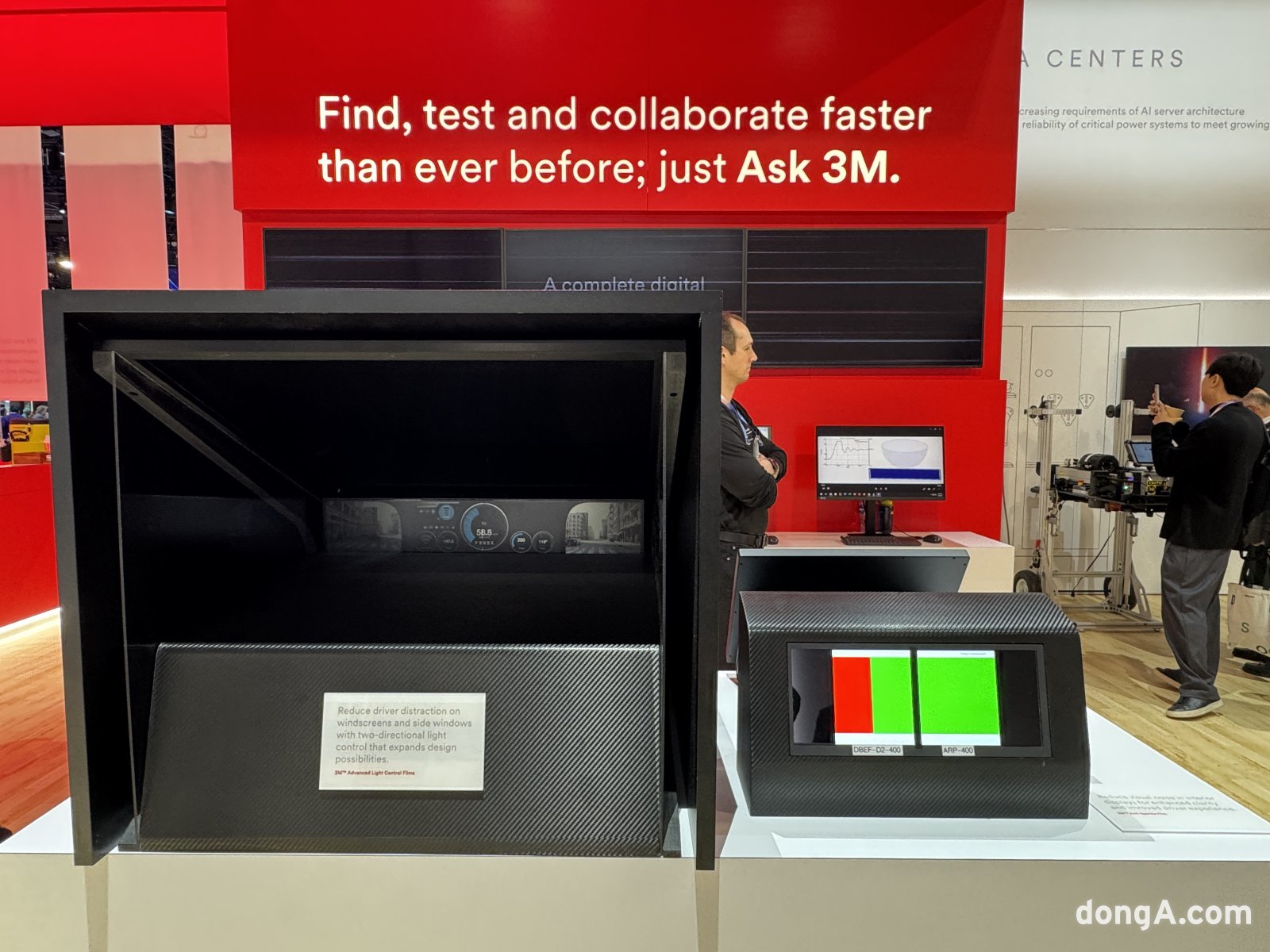

AI‑based digital materials solutions also drew attention at the CES venue. “Ask 3M” is a system in which AI proposes suitable solutions when users enter technical questions about adhesives and materials. The “Digital Materials Hub” digitizes physical property data of 3M products so that customers can use them directly at the design stage. This supports design efficiency and process optimization not only in data centers but also in the automotive industry.

3M also introduced sensor technology that automatically measures and controls the mixing ratio of two‑component adhesives, as well as an automation system that precisely applies VHB adhesive for electronic products. According to the company, bonding of some components can be completed in about seven seconds.

Amy McLaughlin, president of the Advanced Materials and Mobility Product Platform at 3M, said, “3M is presenting solutions that simultaneously enhance safety, convenience, and efficiency in the automotive industry through the convergence of materials and digital technologies,” and added, “Through this year’s CES exhibition, 3M demonstrates that materials technology can be a source of competitive advantage in the era of future vehicles.”

Jeong Jin-su

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News