Startup

Aimusli’s Vision for Next-Gen Semiconductor Manufacturing AI

Dong-A Ilbo |

Updated 2025.12.17

[Seoul Center for Creative Economy & Innovation x ITDongA] Challenge! K-Startup is the largest start-up competition in Korea, jointly hosted by 10 government ministries. Among its various tracks, the Seoul Center for Creative Economy & Innovation operates the general division of the Innovation Startup League. ITDongA takes a look at promising startups that have grown together with the Seoul Center for Creative Economy & Innovation.

“It feels like too much of an honor that Amfusly received the Excellence Award; rather, it makes us feel a stronger sense of responsibility. We do not yet have tangible achievements to show, so the award reflects high expectations for our future potential. While we are delighted, it also feels like encouragement and a spur to do better than we are now. The day of the award ceremony was a day for all Amfusly executives and staff to laugh and celebrate together, and from now on we are thinking hard about how to repay this recognition.”

On 12 December, the “Challenge! K-Startup” event, the largest startup competition in Korea organized by the Ministry of SMEs and Startups and the Korea Institute of Startup & Entrepreneurship Development, with participation from 10 government ministries, local governments, and universities, concluded its 10-month schedule. This year’s competition saw 7,377 teams compete, up from 6,238 teams last year, and only 225 teams advanced to the integrated finals through a total of 12 leagues.

After another round of finals, 15 teams each were selected in the Preliminary Startup League and the Startup League, and Amfusly won an Excellence Award. Out of 7,377 companies, its technology and competitiveness were recognized. ITDongA sat down with CEO Choi Seung-cheon of Amfusly to hear about the journey from applying to the Innovation Startup League through to the results.

Engaged in advanced semiconductor process control work… Founded in August 2024

CEO Choi Seung-cheon of Amfusly earned his master’s and doctoral degrees in mechanical engineering from UC Berkeley and has worked in advanced manufacturing sites since 2003, making him an industry expert. He worked at Hanwha as a production technology engineer for aerospace and defense components, and at Corning, where he developed technologies to improve the productivity of glass processing processes for TFT-LCD display substrates, particularly edge processing.

From 2019, he joined SK hynix, where he designed and implemented R2R (Run-to-Run) process control algorithms for semiconductor manufacturing, including adaptive model tuning and automatic updates using customized web apps. Through this, he led improvements in process stability and yield using data-driven and machine-learning technologies. Specifically, while working on applying data- and AI-based Advanced Process Control (APC) to semiconductor mass production, he realized there were inherent limits to process stability and scalability with existing approaches alone. To implement a new process control architecture that would address these issues, he founded Amfusly.

Amfusly is developing Amfibian, an AI platform that uses semiconductor manufacturing process data to support real-time process control and optimization. CEO Choi said, “I studied manufacturing at school, but once I was on the factory floor, I realized how difficult it was to apply what I had learned. From my first job, I wanted to solve this problem, and as I advanced intelligent APC technologies at SK hynix, I arrived at an answer. In November 2023, SK hynix launched its in-house startup program ‘Hi-Garage,’ I applied, was selected, and started the business in August 2024.”

Amfusly’s semiconductor APC-support AI platform ‘Amfibian’

He was asked how his experience at SK hynix led to Amfusly, and what kind of service Amfibian provides. CEO Choi explained, “In semiconductor processes, recipes are optimized during the R&D phase, and in mass production these recipes are tuned to ensure consistent quality and performance. So a Run-to-Run (R2R) process method is used, continuously optimizing the next process execution based on the results of the previous lot, and APC is used to finely tune and optimize the process recipe each time.”

He continued, “Manufacturing just one type of semiconductor requires hundreds of processes, and each client has different design and process requirements. Ultimately, responding to all this demand requires different APC models for hundreds of thousands of cases, and they must constantly be adjusted as materials or requirements change. The problem is that this tuning process still relies on individual experience—what is often called ‘know-how.’ Companies do not share this with each other, and it is seldom openly shared even internally. Amfibian structures this entire process as data, turns it into a platform, and automates it.”

CEO Choi compared advanced semiconductor process control to a franchise restaurant. He said, “A franchise restaurant has fixed recipes, but the ingredients that arrive each day are slightly different. Nevertheless, the chef must produce a taste that is as similar as possible using those varying ingredients, and that depends on the chef’s discretion. Semiconductor APC is similar. There is a base process recipe, and it must be manipulated slightly to produce products with as consistent performance as possible. Automating this approach is the role of Amfibian.”

Amfibian can be used across semiconductor processes that are based on Run-to-Run control, excluding lithography. Lithography is excluded because it involves a very large number of parameters, requires a different modeling approach, and the equipment itself operates with a highly sophisticated control system. Beyond semiconductors, it can also be extended to other Run-to-Run processes such as batteries and displays, as well as process-based industries such as refining, chemicals, and pharmaceuticals.

“The Innovation Startup League at Seoul Center for Creative Economy & Innovation is very open, so competition is fierce”

Amfusly chose to submit its technology to Seoul Center for Creative Economy & Innovation among the 12 leagues because of its confidence in its technology and the flexibility of the participation criteria. For example, the Environment League, the New Real Estate Industry League, and the Intellectual Property League accept only companies in the respective related sectors. In contrast, the general division of the Innovation Startup League is open to prospective entrepreneurs and companies founded within three years. This makes the competition more intense, but CEO Choi felt confident. He also noted that GORE Robotics and Amber Road, which started as in-house ventures at POSCO last year, won the Grand Prize and Excellence Award, respectively, at Challenge! K-Startup, which led him to believe that Amfusly, as an in-house venture of SK hynix, would also be competitive.

CEO Choi said, “We became connected with the Seoul Center for Creative Economy & Innovation when we advanced to the finals of the Innovation Startup League. We are now registered as an incubated company at Seoul Center, and we receive support such as IR pitching consulting and investor mentoring. In August, we were introduced to Hyundai Motor Securities through the Challenge! K-Startup 2025 Meetup Day, and at the end of this December, there will be another Partners Meetup Day for the Innovation Startup League of Challenge! K-Startup. Having signed an agreement, we expect to receive support in various areas going forward.”

“I believed Amfusly would emerge as a notable player amid this year’s focus on semiconductors in the second half”

Regarding the background to winning the Excellence Award, he said, “We emphasized that we are in the semiconductor sector and, more specifically, that we are one of the rare companies focusing on semiconductor manufacturing AI,” adding, “Anyone can come up with an idea, but we have moved beyond the idea stage and realized it. Having worked at SK hynix, we have the relevant know-how, and we managed to implement the idea up to the Minimum Viable Product (MVP) stage within one year of founding. I believe we were highly evaluated for delivering results within two years despite being a deep-tech company.”

For potential participants in 2026, CEO Choi said, “Of course I would recommend taking on the challenge. Early-stage startups need to give many presentations to investors to get their name out and secure funding. By participating in the Innovation Startup League, they can practice IR pitching without too much pressure and, in some cases, even receive business evaluations. It is helpful in all aspects—recruitment, external promotion, and practice. Also, the support comes as prize money, not government funding tied to specific performance outcomes, so it is ideal in that the CEO can decide freely how to use it.”

All goals achieved this year, 2026 will be a year for ‘support and expansion’

Even while walking the Challenge! K-Startup journey from April to December, CEO Choi steadily delivered results. He said, “Our biggest goal this year was to develop an MVP, which we have already achieved, and we have also succeeded in demonstrating it to customers. It was important to show that Amfusly can meet semiconductor companies’ automation needs, so we presented at the Korean Cleaning Technology Symposium and at ICPT, the largest international conference in the CMP field. We were also selected for programs such as the Initial Startup Package, IBK Changgong, and the TIPS program of the Ministry of SMEs and Startups.”

However, he pointed out that there are areas for improvement in participating in the government’s manufacturing AI support projects, which have recently drawn interest and support. CEO Choi said, “Current AI support programs are divided into manufacturing AI and AI semiconductors, but Amfusly falls under semiconductor manufacturing AI, which does not fit neatly into either category. Manufacturing AI support is currently centered on SMEs, so companies like ours, whose demand-side clients are large enterprises, are excluded. I hope support schemes can also be opened up for companies in this gray area.”

Finally, Amfusly’s goals for next year are to generate revenue and expand its business. CEO Choi said, “Next year we must translate the MVP into actual sales. We received investment last year, so now it is time to prove ourselves with performance. Rather than focusing on a specific revenue figure, our goal is to have foundries and semiconductor manufacturers use our solution. We also aim to expand our coverage: we are currently focused only on CMP, but we intend to extend into cleaning, deposition, and diffusion. We will concentrate on using Amfibian in more diverse areas and broadening our adoption cases.”

Reporter Nam Si-hyun, ITDongA (sh@itdonga.com)

“It feels like too much of an honor that Amfusly received the Excellence Award; rather, it makes us feel a stronger sense of responsibility. We do not yet have tangible achievements to show, so the award reflects high expectations for our future potential. While we are delighted, it also feels like encouragement and a spur to do better than we are now. The day of the award ceremony was a day for all Amfusly executives and staff to laugh and celebrate together, and from now on we are thinking hard about how to repay this recognition.”

On 12 December, the “Challenge! K-Startup” event, the largest startup competition in Korea organized by the Ministry of SMEs and Startups and the Korea Institute of Startup & Entrepreneurship Development, with participation from 10 government ministries, local governments, and universities, concluded its 10-month schedule. This year’s competition saw 7,377 teams compete, up from 6,238 teams last year, and only 225 teams advanced to the integrated finals through a total of 12 leagues.

CEO Choi Seung-cheon of Amfusly is an industry expert with more than 20 years of experience in advanced manufacturing / Source=ITDongA

After another round of finals, 15 teams each were selected in the Preliminary Startup League and the Startup League, and Amfusly won an Excellence Award. Out of 7,377 companies, its technology and competitiveness were recognized. ITDongA sat down with CEO Choi Seung-cheon of Amfusly to hear about the journey from applying to the Innovation Startup League through to the results.

Engaged in advanced semiconductor process control work… Founded in August 2024

CEO Choi Seung-cheon of Amfusly earned his master’s and doctoral degrees in mechanical engineering from UC Berkeley and has worked in advanced manufacturing sites since 2003, making him an industry expert. He worked at Hanwha as a production technology engineer for aerospace and defense components, and at Corning, where he developed technologies to improve the productivity of glass processing processes for TFT-LCD display substrates, particularly edge processing.

From 2019, he joined SK hynix, where he designed and implemented R2R (Run-to-Run) process control algorithms for semiconductor manufacturing, including adaptive model tuning and automatic updates using customized web apps. Through this, he led improvements in process stability and yield using data-driven and machine-learning technologies. Specifically, while working on applying data- and AI-based Advanced Process Control (APC) to semiconductor mass production, he realized there were inherent limits to process stability and scalability with existing approaches alone. To implement a new process control architecture that would address these issues, he founded Amfusly.

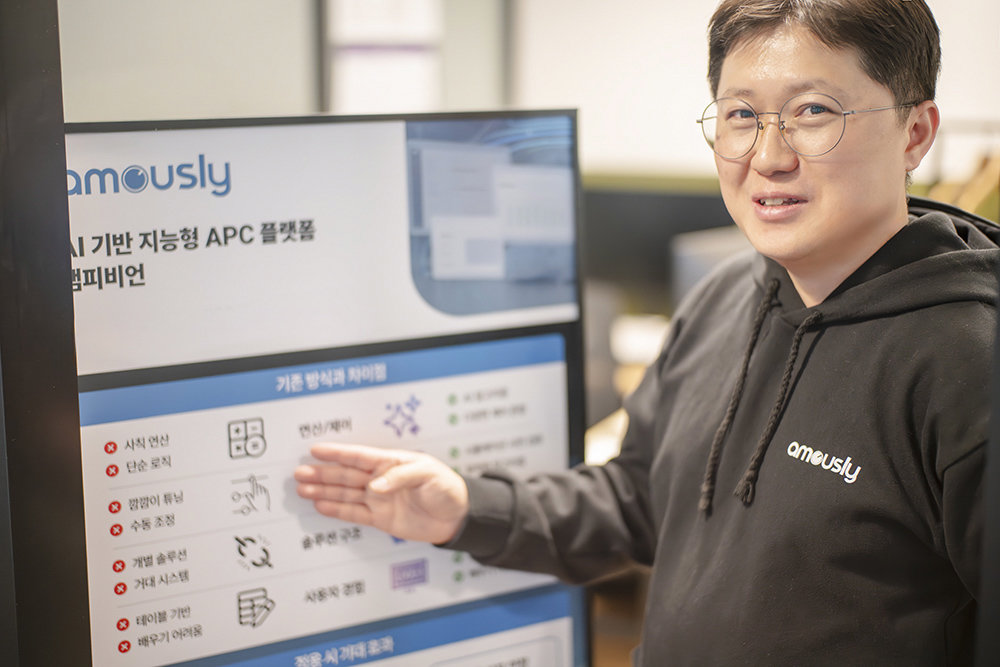

CEO Choi introduces the features of Amfusly’s Amfibian solution / Source=ITDongA

Amfusly is developing Amfibian, an AI platform that uses semiconductor manufacturing process data to support real-time process control and optimization. CEO Choi said, “I studied manufacturing at school, but once I was on the factory floor, I realized how difficult it was to apply what I had learned. From my first job, I wanted to solve this problem, and as I advanced intelligent APC technologies at SK hynix, I arrived at an answer. In November 2023, SK hynix launched its in-house startup program ‘Hi-Garage,’ I applied, was selected, and started the business in August 2024.”

Amfusly’s semiconductor APC-support AI platform ‘Amfibian’

He was asked how his experience at SK hynix led to Amfusly, and what kind of service Amfibian provides. CEO Choi explained, “In semiconductor processes, recipes are optimized during the R&D phase, and in mass production these recipes are tuned to ensure consistent quality and performance. So a Run-to-Run (R2R) process method is used, continuously optimizing the next process execution based on the results of the previous lot, and APC is used to finely tune and optimize the process recipe each time.”

Many parts of semiconductor manufacturing processes are automated, but there are still areas that must be manually controlled / Source=Shutterstock

He continued, “Manufacturing just one type of semiconductor requires hundreds of processes, and each client has different design and process requirements. Ultimately, responding to all this demand requires different APC models for hundreds of thousands of cases, and they must constantly be adjusted as materials or requirements change. The problem is that this tuning process still relies on individual experience—what is often called ‘know-how.’ Companies do not share this with each other, and it is seldom openly shared even internally. Amfibian structures this entire process as data, turns it into a platform, and automates it.”

CEO Choi compared advanced semiconductor process control to a franchise restaurant. He said, “A franchise restaurant has fixed recipes, but the ingredients that arrive each day are slightly different. Nevertheless, the chef must produce a taste that is as similar as possible using those varying ingredients, and that depends on the chef’s discretion. Semiconductor APC is similar. There is a base process recipe, and it must be manipulated slightly to produce products with as consistent performance as possible. Automating this approach is the role of Amfibian.”

Amfibian can be used across semiconductor processes that are based on Run-to-Run control, excluding lithography. Lithography is excluded because it involves a very large number of parameters, requires a different modeling approach, and the equipment itself operates with a highly sophisticated control system. Beyond semiconductors, it can also be extended to other Run-to-Run processes such as batteries and displays, as well as process-based industries such as refining, chemicals, and pharmaceuticals.

“The Innovation Startup League at Seoul Center for Creative Economy & Innovation is very open, so competition is fierce”

The preliminary round of Challenge! K-Startup 2025 was divided into 12 leagues in total. Among them, the Innovation Startup League operated by the Seoul Center for Creative Economy & Innovation had very high competition due to its minimal participation restrictions / Source=Korea Institute of Startup & Entrepreneurship Development

Amfusly chose to submit its technology to Seoul Center for Creative Economy & Innovation among the 12 leagues because of its confidence in its technology and the flexibility of the participation criteria. For example, the Environment League, the New Real Estate Industry League, and the Intellectual Property League accept only companies in the respective related sectors. In contrast, the general division of the Innovation Startup League is open to prospective entrepreneurs and companies founded within three years. This makes the competition more intense, but CEO Choi felt confident. He also noted that GORE Robotics and Amber Road, which started as in-house ventures at POSCO last year, won the Grand Prize and Excellence Award, respectively, at Challenge! K-Startup, which led him to believe that Amfusly, as an in-house venture of SK hynix, would also be competitive.

CEO Choi said, “We became connected with the Seoul Center for Creative Economy & Innovation when we advanced to the finals of the Innovation Startup League. We are now registered as an incubated company at Seoul Center, and we receive support such as IR pitching consulting and investor mentoring. In August, we were introduced to Hyundai Motor Securities through the Challenge! K-Startup 2025 Meetup Day, and at the end of this December, there will be another Partners Meetup Day for the Innovation Startup League of Challenge! K-Startup. Having signed an agreement, we expect to receive support in various areas going forward.”

“I believed Amfusly would emerge as a notable player amid this year’s focus on semiconductors in the second half”

The awards ceremony of the 2025 Challenge! K-Startup Grand Finale held on the 12th / Source=Amfusly

Regarding the background to winning the Excellence Award, he said, “We emphasized that we are in the semiconductor sector and, more specifically, that we are one of the rare companies focusing on semiconductor manufacturing AI,” adding, “Anyone can come up with an idea, but we have moved beyond the idea stage and realized it. Having worked at SK hynix, we have the relevant know-how, and we managed to implement the idea up to the Minimum Viable Product (MVP) stage within one year of founding. I believe we were highly evaluated for delivering results within two years despite being a deep-tech company.”

For potential participants in 2026, CEO Choi said, “Of course I would recommend taking on the challenge. Early-stage startups need to give many presentations to investors to get their name out and secure funding. By participating in the Innovation Startup League, they can practice IR pitching without too much pressure and, in some cases, even receive business evaluations. It is helpful in all aspects—recruitment, external promotion, and practice. Also, the support comes as prize money, not government funding tied to specific performance outcomes, so it is ideal in that the CEO can decide freely how to use it.”

All goals achieved this year, 2026 will be a year for ‘support and expansion’

Lastly, CEO Choi called for support not only for manufacturing AI and AI semiconductors, but also for specialized areas such as semiconductor manufacturing AI / Source=ITDongA

Even while walking the Challenge! K-Startup journey from April to December, CEO Choi steadily delivered results. He said, “Our biggest goal this year was to develop an MVP, which we have already achieved, and we have also succeeded in demonstrating it to customers. It was important to show that Amfusly can meet semiconductor companies’ automation needs, so we presented at the Korean Cleaning Technology Symposium and at ICPT, the largest international conference in the CMP field. We were also selected for programs such as the Initial Startup Package, IBK Changgong, and the TIPS program of the Ministry of SMEs and Startups.”

However, he pointed out that there are areas for improvement in participating in the government’s manufacturing AI support projects, which have recently drawn interest and support. CEO Choi said, “Current AI support programs are divided into manufacturing AI and AI semiconductors, but Amfusly falls under semiconductor manufacturing AI, which does not fit neatly into either category. Manufacturing AI support is currently centered on SMEs, so companies like ours, whose demand-side clients are large enterprises, are excluded. I hope support schemes can also be opened up for companies in this gray area.”

Finally, Amfusly’s goals for next year are to generate revenue and expand its business. CEO Choi said, “Next year we must translate the MVP into actual sales. We received investment last year, so now it is time to prove ourselves with performance. Rather than focusing on a specific revenue figure, our goal is to have foundries and semiconductor manufacturers use our solution. We also aim to expand our coverage: we are currently focused only on CMP, but we intend to extend into cleaning, deposition, and diffusion. We will concentrate on using Amfibian in more diverse areas and broadening our adoption cases.”

Reporter Nam Si-hyun, ITDongA (sh@itdonga.com)

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News