Medical / Medical Device

Stacle Aims to Transform Hospital Transport With EV Tech

Dong-A Ilbo |

Updated 2025.12.15

[SeoulTech x IT Donga Joint Project] The Preliminary Startup Package Support Program (hereinafter referred to as the “Preliminary Startup Package”) is a major startup support initiative of the Ministry of SMEs and Startups and the Korea Institute of Startup & Entrepreneurship Development that helps turn promising ideas into businesses. As an operating institution for the 2025 Preliminary Startup Package, the Startup Support Group of Seoul National University of Science and Technology (SeoulTech) will support the growth and development of early-stage companies. In cooperation with SeoulTech’s Startup Support Group, IT Donga is introducing promising startups currently in growth.

Walking down hospital corridors, it is common to see nurses pushing beds carrying patients. It appears ordinary, but it reflects the difficulties of the medical field. On average, 2–3 medical staff members are needed to transport a single patient, but due to chronic staffing shortages, it is common for just one person to be forced to push the bed. Such physically demanding work causes musculoskeletal disorders among medical staff and ultimately leads to a decline in the quality of medical services and staff turnover.

According to the 2023 paper “Analysis of Characteristics of Occupational Diseases and Epidemiological Survey Cases of Medical Institution Workers from 2010 to 2019,” published by the Occupational Safety and Health Research Institute and the Department of Nursing at the University of Ulsan, musculoskeletal disorders accounted for 66.9% of occupational diseases approved for compensation among medical institution workers, the highest share among all categories.

Advanced medical countries overseas are actively developing powered equipment to assist with bed transportation to address these problems. By contrast, the domestic market is still in the early stages of adopting such powered devices. They are expensive, and awareness of the need for such equipment remains low. The situation is relatively better in university hospitals, but small and mid-sized hospitals struggle to introduce powered transfer equipment due to budget constraints.

A startup has stepped forward with the ambition to innovate the patient transport environment in Korean hospitals: Starcle, which is leveraging modular electrification technology. With the goal of protecting the health of medical staff and providing a safe transport environment for patients, Starcle is focusing on commercializing a detachable powered patient bed transfer device (hereinafter referred to as the “bed transfer device”). What kind of transport environment innovation does Starcle envision? IT Donga interviewed Starcle CEO Bae Su-chan.

Preparing for entrepreneurship by observing the medical field

“The difficulties surrounding patient transport in domestic hospitals were confirmed directly on site. Many medical staff complain of wrist, back, and shoulder pain during the process of moving patients. Meanwhile, the spread of powered technologies for patient transport in Korean hospitals has remained stagnant, despite such technologies already being commonplace overseas. I recognized that if this situation continues, it will harm the health of medical staff and reduce work efficiency.”

Starcle is a mobility startup developing hospital bed transport robots. Rather than developing new beds from scratch, it has created a power-assist device that uses existing beds and helps move heavy beds with minimal effort.

Why did the company decide to pursue technological innovation in hospital bed transport? CEO Bae gained experience at a company that manufactures and sells hospital meal delivery carts, where he saw first-hand the challenges of transport in medical settings. The load involved is so great that moving a single hospital bed can require the strength of two adult men. The burden on nurses who must sometimes transport patients alone at night or in emergencies is particularly severe. Bae thought that solving this problem would help improve the domestic medical environment.

The turning point came from a doctor working at a hospital in Daejeon. Having experienced the medical environment in Australia, this doctor asked the powered equipment company where Bae worked, “Why are there no powered patient transfer devices in Korea?” The doctor added that while patients are easily transported using powered equipment overseas, it was strange to see Korea rely solely on human strength. After hearing this, Bae deliberated and decided to start a business.

As Starcle moved in earnest into the development of hospital bed transport robots, it focused on the “voice of the field.” Bae believes that, for manufacturing to succeed, it is essential to accurately identify and resolve user inconveniences. “The answer is always on site,” he said. “No matter how advanced the technology, it is useless if it is inconvenient in actual use environments.”

Differentiation through “detachable” technology

Starcle’s product is a bed transfer device. CEO Bae emphasizes that its differentiation lies in its “detachable” technology. Many powered beds developed by domestic companies use an integrated design in which the motor is built into the bed. While this does not pose difficulties for general use, problems arise when patients enter operating rooms or examination rooms. In Korean hospitals, once a patient enters an operating room or examination room, the bed is typically left idle in the corridor until the patient returns. In emergencies, these idle beds cannot be used, leading to a decline in bed utilization rates.

By contrast, the bed transfer device is designed so that the equipment is inserted under the bed when needed for transport and then separated immediately afterward. Because only the powered equipment needs to be attached or detached, bed operations can remain flexible.

The driving function is tailored to domestic hospital environments. Taking into account the narrow corridors and numerous elevators typical of Korean hospitals, the device is designed to rotate on the spot. A single joystick connected to the powered unit enables 360-degree and precision turning, allowing a single operator to easily move even large patients in tight spaces.

To enhance the technological completeness of the product, Bae personally oversees the entire process, including mechanical design, electrical design, hardware, and software integration. This hands-on involvement translates into strong after-sales support capabilities. By using domestic manufacturing facilities, the company can respond relatively quickly to parts procurement and maintenance needs.

The primary target customers for the bed transfer device are small and mid-sized hospitals. Unlike well-funded university hospitals, small and mid-sized hospitals often face shortages of both personnel and funds, making it difficult in practice to introduce high-priced equipment. In response, Starcle plans to first supply bed transfer devices to university hospitals, gather sufficient data, and then use that data to persuade small and mid-sized hospitals.

The company also stresses advantages in terms of total cost of ownership (TCO). According to Starcle, using 20 powered bed transfer devices in Australia can reduce annual costs by approximately KRW 50 million. “We plan to emphasize that improving work efficiency generates sufficient long-term returns on investment,” Bae said. “We aim to encourage small and mid-sized hospitals to adopt bed transfer devices at reasonable prices.”

Aiming to innovate patient transport environments through technology

Having showcased its product at Korea Electronics Show (KES) 2025 to gauge market reactions, Starcle has designated 2026 as the first year of commercializing its bed transfer device. The company plans to participate in international medical device exhibitions and related academic conferences to promote its product. It also aims to obtain medical device certifications and register with the Public Procurement Service to enter the public hospital market.

As Starcle focuses on enhancing the completeness of its bed transfer device, one challenge is adapting to the varying bed specifications of different manufacturers. Patient beds used in domestic hospitals differ in frame structure, height, and wheel shapes, making it difficult to apply a single device uniformly.

Starcle intends to overcome this challenge with a “modular powered kit.” By modularizing the brackets attached to the underside of beds, the company aims to ensure compatibility with beds from any manufacturer, without requiring modification, thereby securing universality. “In line with our principle of finding answers in the field, we focused on understanding the structural characteristics of patient beds used in domestic hospitals,” Bae explained. “As a result, we developed a connection structure compatible with various bed models and have filed patent applications. With overseas market entry in mind, we plan to concentrate on product completeness.”

SeoulTech’s support has played a role in helping Starcle realize its vision of innovating the hospital transport environment. Selected for SeoulTech Startup Support Group’s Preliminary Startup Package program, Starcle received assistance for most stages, from the planning of the bed transfer device through to prototype production. The company was also provided with mentoring on business direction and networking opportunities with related industries. “We received support from SeoulTech in multiple areas, including prototype development and preparations for demonstration testing,” Bae said. “Thanks to the Preliminary Startup Package program, we were able to establish a foothold for engaging with the medical market.”

“We want to automate all patient transport processes. The goal is to create an environment where medical staff no longer get injured and patients are transported safely. We want to become a company that brings smiles to nurses, medical staff, and patients alike.”

Starcle’s ultimate objective is the automation of hospital transport systems. Although the company is currently developing powered equipment that pushes beds, Bae explained that the ambition is to automate even the transfer of patients from bed to bed. He also presented a roadmap for using robotics technology to innovate all forms of in-hospital movement, including bed-to-bed linked transport, and the delivery of medications and specimens.

IT Donga reporter Kang Hyeong-seok (redbk@itdonga.com)

Walking down hospital corridors, it is common to see nurses pushing beds carrying patients. It appears ordinary, but it reflects the difficulties of the medical field. On average, 2–3 medical staff members are needed to transport a single patient, but due to chronic staffing shortages, it is common for just one person to be forced to push the bed. Such physically demanding work causes musculoskeletal disorders among medical staff and ultimately leads to a decline in the quality of medical services and staff turnover.

According to the 2023 paper “Analysis of Characteristics of Occupational Diseases and Epidemiological Survey Cases of Medical Institution Workers from 2010 to 2019,” published by the Occupational Safety and Health Research Institute and the Department of Nursing at the University of Ulsan, musculoskeletal disorders accounted for 66.9% of occupational diseases approved for compensation among medical institution workers, the highest share among all categories.

Advanced medical countries overseas are actively developing powered equipment to assist with bed transportation to address these problems. By contrast, the domestic market is still in the early stages of adopting such powered devices. They are expensive, and awareness of the need for such equipment remains low. The situation is relatively better in university hospitals, but small and mid-sized hospitals struggle to introduce powered transfer equipment due to budget constraints.

Bae Su-chan, CEO of Starcle / Source = IT Donga

A startup has stepped forward with the ambition to innovate the patient transport environment in Korean hospitals: Starcle, which is leveraging modular electrification technology. With the goal of protecting the health of medical staff and providing a safe transport environment for patients, Starcle is focusing on commercializing a detachable powered patient bed transfer device (hereinafter referred to as the “bed transfer device”). What kind of transport environment innovation does Starcle envision? IT Donga interviewed Starcle CEO Bae Su-chan.

Preparing for entrepreneurship by observing the medical field

“The difficulties surrounding patient transport in domestic hospitals were confirmed directly on site. Many medical staff complain of wrist, back, and shoulder pain during the process of moving patients. Meanwhile, the spread of powered technologies for patient transport in Korean hospitals has remained stagnant, despite such technologies already being commonplace overseas. I recognized that if this situation continues, it will harm the health of medical staff and reduce work efficiency.”

Starcle is a mobility startup developing hospital bed transport robots. Rather than developing new beds from scratch, it has created a power-assist device that uses existing beds and helps move heavy beds with minimal effort.

Why did the company decide to pursue technological innovation in hospital bed transport? CEO Bae gained experience at a company that manufactures and sells hospital meal delivery carts, where he saw first-hand the challenges of transport in medical settings. The load involved is so great that moving a single hospital bed can require the strength of two adult men. The burden on nurses who must sometimes transport patients alone at night or in emergencies is particularly severe. Bae thought that solving this problem would help improve the domestic medical environment.

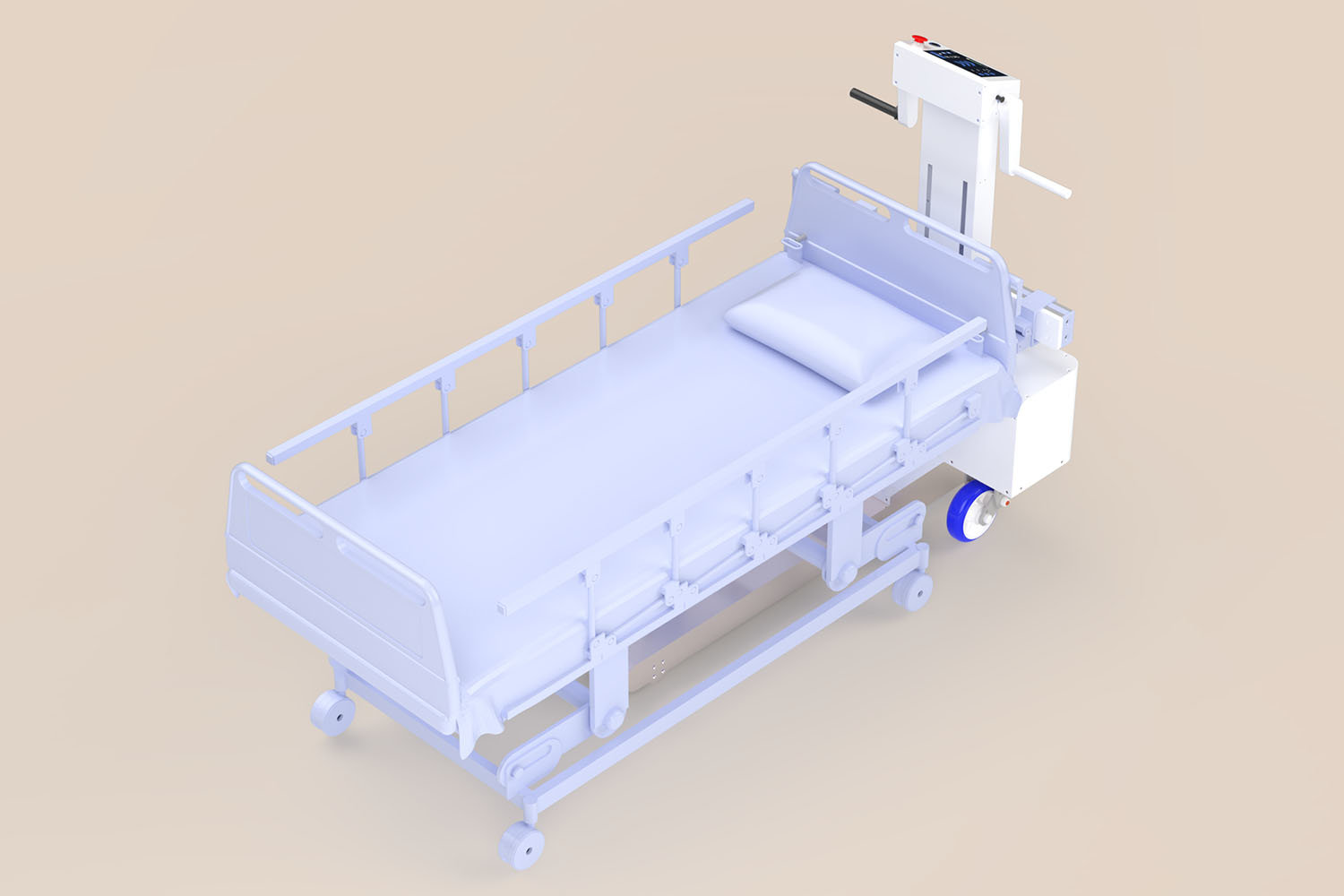

Type-A bed transfer device under development by Starcle / Source = Starcle

The turning point came from a doctor working at a hospital in Daejeon. Having experienced the medical environment in Australia, this doctor asked the powered equipment company where Bae worked, “Why are there no powered patient transfer devices in Korea?” The doctor added that while patients are easily transported using powered equipment overseas, it was strange to see Korea rely solely on human strength. After hearing this, Bae deliberated and decided to start a business.

As Starcle moved in earnest into the development of hospital bed transport robots, it focused on the “voice of the field.” Bae believes that, for manufacturing to succeed, it is essential to accurately identify and resolve user inconveniences. “The answer is always on site,” he said. “No matter how advanced the technology, it is useless if it is inconvenient in actual use environments.”

Differentiation through “detachable” technology

Starcle’s product is a bed transfer device. CEO Bae emphasizes that its differentiation lies in its “detachable” technology. Many powered beds developed by domestic companies use an integrated design in which the motor is built into the bed. While this does not pose difficulties for general use, problems arise when patients enter operating rooms or examination rooms. In Korean hospitals, once a patient enters an operating room or examination room, the bed is typically left idle in the corridor until the patient returns. In emergencies, these idle beds cannot be used, leading to a decline in bed utilization rates.

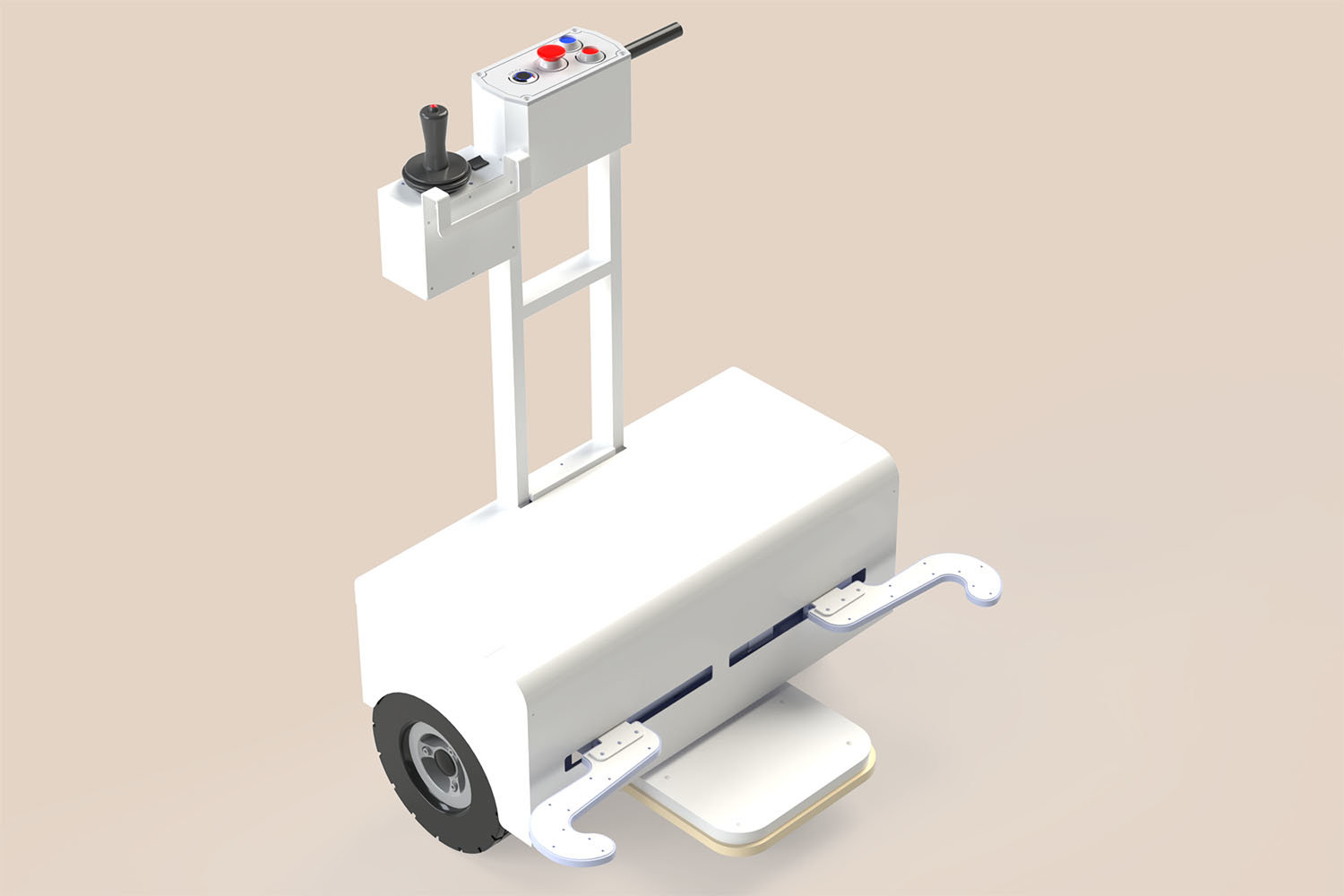

By contrast, the bed transfer device is designed so that the equipment is inserted under the bed when needed for transport and then separated immediately afterward. Because only the powered equipment needs to be attached or detached, bed operations can remain flexible.

The driving function is tailored to domestic hospital environments. Taking into account the narrow corridors and numerous elevators typical of Korean hospitals, the device is designed to rotate on the spot. A single joystick connected to the powered unit enables 360-degree and precision turning, allowing a single operator to easily move even large patients in tight spaces.

To enhance the technological completeness of the product, Bae personally oversees the entire process, including mechanical design, electrical design, hardware, and software integration. This hands-on involvement translates into strong after-sales support capabilities. By using domestic manufacturing facilities, the company can respond relatively quickly to parts procurement and maintenance needs.

Type-B bed transfer device under development by Starcle / Source = Starcle

The primary target customers for the bed transfer device are small and mid-sized hospitals. Unlike well-funded university hospitals, small and mid-sized hospitals often face shortages of both personnel and funds, making it difficult in practice to introduce high-priced equipment. In response, Starcle plans to first supply bed transfer devices to university hospitals, gather sufficient data, and then use that data to persuade small and mid-sized hospitals.

The company also stresses advantages in terms of total cost of ownership (TCO). According to Starcle, using 20 powered bed transfer devices in Australia can reduce annual costs by approximately KRW 50 million. “We plan to emphasize that improving work efficiency generates sufficient long-term returns on investment,” Bae said. “We aim to encourage small and mid-sized hospitals to adopt bed transfer devices at reasonable prices.”

Aiming to innovate patient transport environments through technology

Having showcased its product at Korea Electronics Show (KES) 2025 to gauge market reactions, Starcle has designated 2026 as the first year of commercializing its bed transfer device. The company plans to participate in international medical device exhibitions and related academic conferences to promote its product. It also aims to obtain medical device certifications and register with the Public Procurement Service to enter the public hospital market.

As Starcle focuses on enhancing the completeness of its bed transfer device, one challenge is adapting to the varying bed specifications of different manufacturers. Patient beds used in domestic hospitals differ in frame structure, height, and wheel shapes, making it difficult to apply a single device uniformly.

Starcle intends to overcome this challenge with a “modular powered kit.” By modularizing the brackets attached to the underside of beds, the company aims to ensure compatibility with beds from any manufacturer, without requiring modification, thereby securing universality. “In line with our principle of finding answers in the field, we focused on understanding the structural characteristics of patient beds used in domestic hospitals,” Bae explained. “As a result, we developed a connection structure compatible with various bed models and have filed patent applications. With overseas market entry in mind, we plan to concentrate on product completeness.”

Bae Su-chan, CEO of Starcle / Source = IT Donga

SeoulTech’s support has played a role in helping Starcle realize its vision of innovating the hospital transport environment. Selected for SeoulTech Startup Support Group’s Preliminary Startup Package program, Starcle received assistance for most stages, from the planning of the bed transfer device through to prototype production. The company was also provided with mentoring on business direction and networking opportunities with related industries. “We received support from SeoulTech in multiple areas, including prototype development and preparations for demonstration testing,” Bae said. “Thanks to the Preliminary Startup Package program, we were able to establish a foothold for engaging with the medical market.”

“We want to automate all patient transport processes. The goal is to create an environment where medical staff no longer get injured and patients are transported safely. We want to become a company that brings smiles to nurses, medical staff, and patients alike.”

Starcle’s ultimate objective is the automation of hospital transport systems. Although the company is currently developing powered equipment that pushes beds, Bae explained that the ambition is to automate even the transfer of patients from bed to bed. He also presented a roadmap for using robotics technology to innovate all forms of in-hospital movement, including bed-to-bed linked transport, and the delivery of medications and specimens.

IT Donga reporter Kang Hyeong-seok (redbk@itdonga.com)

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News