Startup / AI

“Week’s Work Done in 10 Minutes: Startup Targets KRW 135 Trillion Robot Design Market”

Dong-A Ilbo |

Updated 2025.12.13

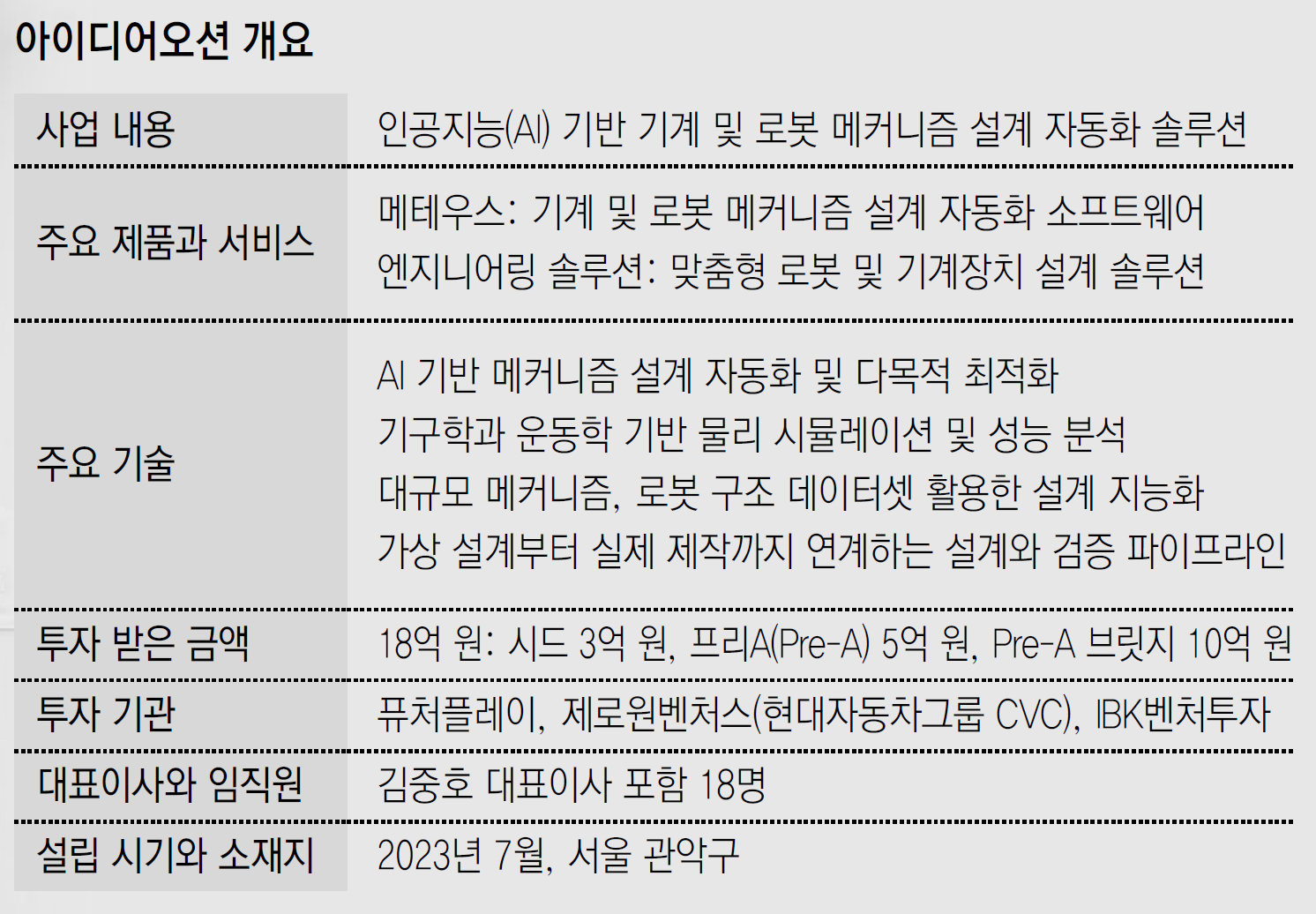

IdeaOcean, the world’s first AI-based mechanism design automation

Automatically generates every mechanism needed for machine operation—just enter goals and constraints

Built its own physics-based AI on 18 years of research by advisor Professor Yoon-Young Kim

Completed technology projects for Hyundai Motor and Samsung Electronics… “There will be many designs humanity has never conceived before”

Automatically generates every mechanism needed for machine operation—just enter goals and constraints

Built its own physics-based AI on 18 years of research by advisor Professor Yoon-Young Kim

Completed technology projects for Hyundai Motor and Samsung Electronics… “There will be many designs humanity has never conceived before”

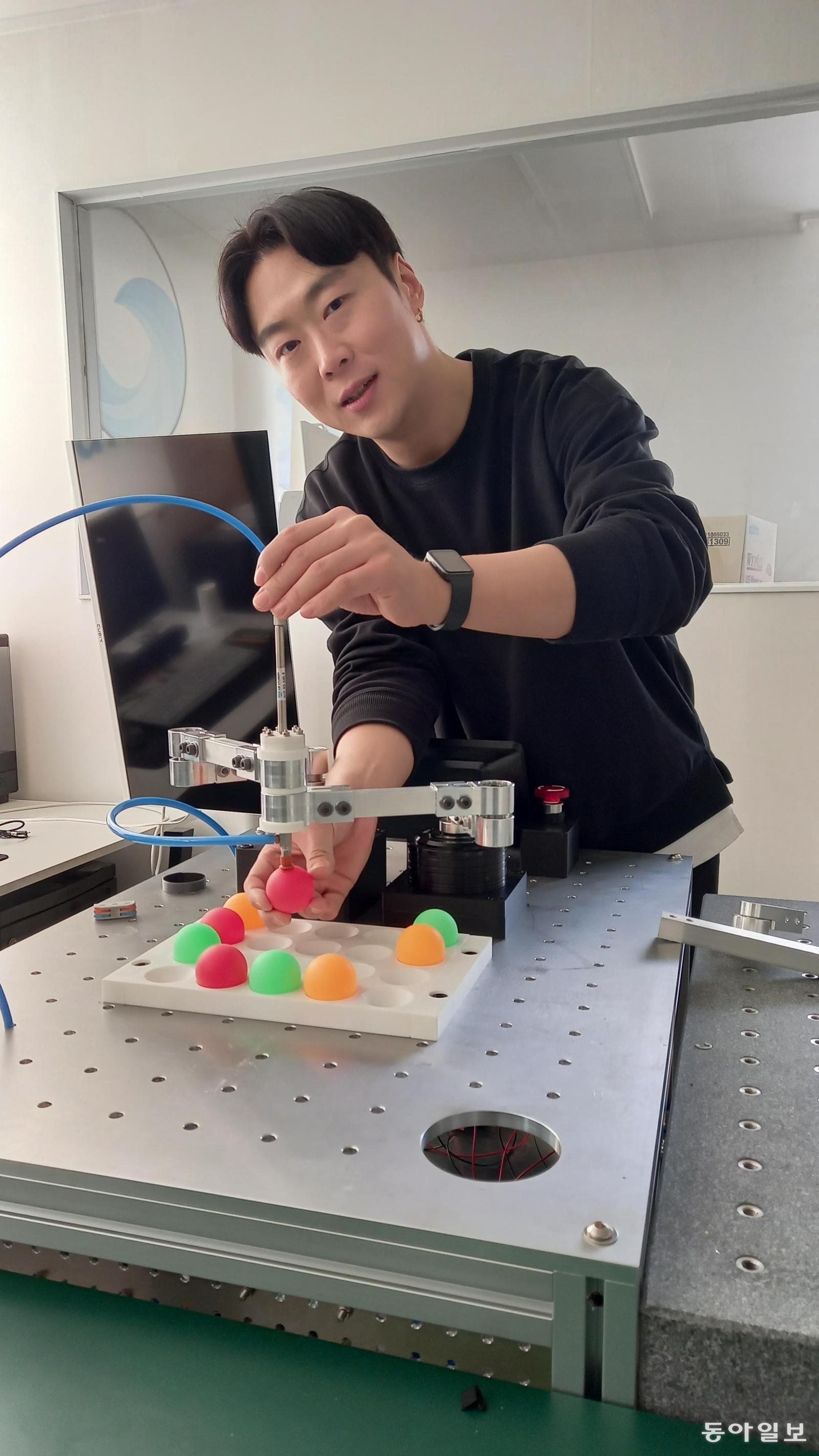

On 9 December, IdeaOcean CEO Kim Jung-ho explains how a robot arm that transfers ping pong balls operates, at the company’s headquarters in Gwanak District, Seoul. The robot arm was created to verify the performance of the company’s automated mechanism design solution. Kim said, “It completed the transfer task much faster and at far lower cost than a general-purpose robot arm.”

“Designing robots or mechanical devices usually requires highly skilled master’s and PhD-level engineers to work on the task for more than a week. They have to conceive and design the structure and then repeatedly run computer simulations to check whether it functions properly. This process is shortened by artificial intelligence (AI), reducing work that used to take a week to just 10 minutes.”Meeting at IdeaOcean’s office in Gwanak District, Seoul, on 9 December, CEO Kim Jung-ho (32) demonstrated the company’s automated mechanism design solution “METHEUS” and made these remarks. Founded in July 2023, IdeaOcean has drawn attention for automating mechanism design—previously dependent on human intuition—using mathematical models and AI technology. Mechanism refers to the structure of links (frames) and joints used in robots or mechanical systems to convert the rotational power of a motor into specific movements.

● Mechanism design by hand

Currently, mechanism design for robots or mechanical systems still largely remains a manual process. Engineers rely on their own experience to conceptualize links and joints and then design them one by one using CAD programs by placing points and drawing lines. The problem arises afterwards. Once a 3D model is created and a computer-aided engineering (CAE) program is run to simulate and analyze forces and performance, any errors discovered require engineers to go back to the beginning and overhaul the design. Kim said, “Because the design and analysis programs are different and both are expensive, even with specialists involved, a great deal of time and cost is consumed in trial and error.”

● Automatic design of operating structures by inputting conditions

IdeaOcean’s METHEUS automatically generates optimal mechanisms when users input conditions such as the desired function, operating range, obstacle locations, and motor positions. Users can also choose design objectives, such as minimizing weight or minimizing cost.

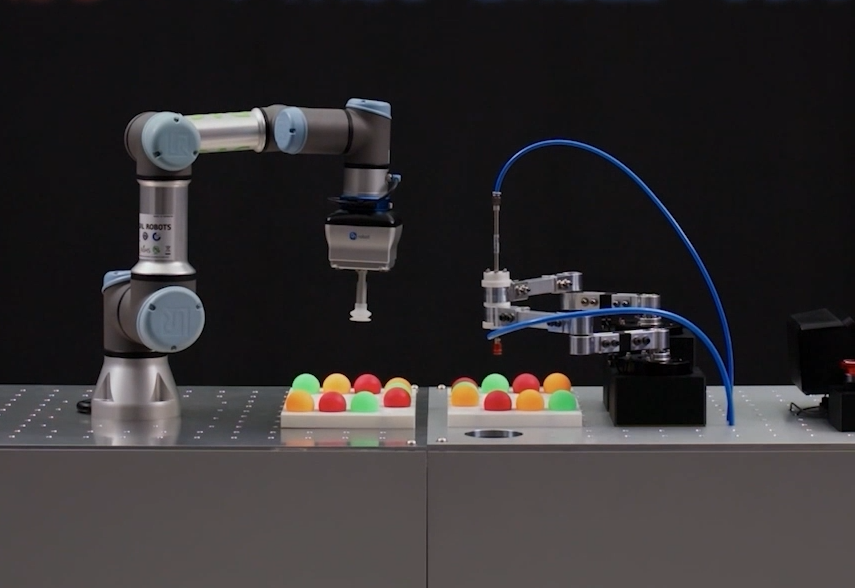

IdeaOcean’s robot arm (right) and a general-purpose robot arm compete to transfer ping pong balls. Provided by IdeaOcean

To verify the automation capabilities of METHEUS, IdeaOcean built a robot arm that transfers ping pong balls and pitted it against a general-purpose robot arm (Universal Robots). “Thanks to a structure optimized by eliminating unnecessary functions, the robot designed by METHEUS cost only one-tenth as much to build, but operated twice as fast,” Kim said. While the general-purpose robot arm can perform tasks such as picking up objects or pouring water from a cup, the ping pong ball transfer robot is optimally designed for that specific task. “By simplifying the design process, there will no longer be a need to purchase expensive general-purpose robots for such tasks,” Kim added.IdeaOcean aims to officially launch METHEUS in September next year. The company is working with large corporations to improve user convenience. The product will be offered in various formats: an on-premise version for large companies with strict security requirements, a subscription model for SMEs and educational use, and plug-ins for existing CAD users. IdeaOcean estimates the size of the robot and mechanical design market at KRW 135 trillion.

● Physics-based AI that does not lie

IdeaOcean’s booth at CES 2024, the world’s largest IT and consumer electronics trade show, held last year in Las Vegas, USA. IdeaOcean received an Innovation Award in the AI category. Provided by IdeaOcean

METHEUS is a physics-based AI that combines a mathematical model called SBM (Stem Block Mechanism) with deep learning technology. SBM, the core element, is a proprietary mathematical model that simplifies complex operating structures like Lego blocks so they can be automatically designed. The mathematical model has continuously generated hundreds of millions of design options (data) that comply with the laws of physics, and the AI has been trained on this data to perform design tasks optimally. When users input targets, functions, and constraints, the AI rapidly narrows down design candidates using the intuition it has acquired through training. By analyzing and verifying only these candidates, it can find the optimal solution in a short time. During this process, if it finds facts such as “the AI proposed a link length of 10 cm, but plugging it into the formula shows that 9.98 cm is more accurate,” it also refines the design plans. The system then applies information on actual motors, bearings, and links to verify that the design works well in the real world. Finally, it outputs 3D design drawings (CAD files).Large language models (LLMs) such as ChatGPT generate sentences based on probability and can therefore produce hallucinations—fabricated content that is not factual. In contrast, METHEUS is trained only on data consistent with the laws of physics and its results are verified through mathematical models, so such issues do not arise.

The ability to automate mechanism design with AI was made possible thanks to Kim’s academic advisor, Professor Emeritus Kim Yoon-young, formerly of the Department of Mechanical Engineering at Seoul National University. Professor Kim, a world-renowned scholar, has been researching mechanism design automation since 2007. He conceived the SBM concept and has spent 18 years developing it. It is an original approach that separates mechanisms into conceptual connection structures (stems) and functional unit elements (blocks) for design. In effect, it turns mechanism design into a process akin to assembling Lego blocks. Based on this concept, he completed a standardized mathematical model capable of automatically deriving all mechanisms.

● From commercial modules to prototypes by simple assembly

As the domestic machinery manufacturing ecosystem has weakened, finding a factory that can machine parts for prototype production has become extremely difficult. Even when placing orders in China, delivery delays are common. In response, IdeaOcean has also innovated the prototype production process. Based on design data created by METHEUS, the company has established a “standard module” system that enables immediate assembly. It pre-manufactures standardized links, joints, and motors (“muscles”) for this purpose. “We have built a Sim2Real pipeline that ensures designs in virtual space (Sim) function without error in the real world (Real),” Kim said. “This allows us to handle everything from design to prototype verification in a non-stop process.”

The results of prototype testing using actual modules are fed back into METHEUS as data to further enhance AI performance. Even if results are theoretically calculated, factors such as small tolerances in parts and movements reflecting physical characteristics are used again to advance METHEUS. “By using mathematical models and AI to search for optimal designs among all physically possible options, there will be many groundbreaking designs that humanity has not yet discovered,” Kim said.

● Constant interest in proprietary technology with an eye on entrepreneurship

Kim’s entrepreneurial aspirations began in high school when he completed the first cohort of the Young Entrepreneurs Program at POSTECH. Having set his sights early on becoming a business leader with unique, proprietary technology, he met Professor Emeritus Kim during his PhD program in mechanical engineering at Seoul National University and began to realize this dream. Kim published the first paper applying Professor Kim’s SBM to actual robot fabrication in a robotics journal. At that time, he recognized the commercialization potential of academic research. The combination of the professor’s outstanding research and his student’s ambition to start a business led to the founding of IdeaOcean. CTO Lee Jong-jun, a former lab colleague of Kim, joined as a co-founder and took charge of building the physics-based AI.

“SBM is a fundamental technology that expresses every movement in the world—such as robot arms, legs, and automobile hinges—in a single unified mathematical language,” Kim said. “Although leading overseas universities, including Tsinghua University in China, are conducting follow-up research, we are maintaining a significant technological lead.”

Asked about the most challenging part of commercialization, Kim said, “The toughest task was proving that mathematically perfect equations could overcome the physical errors and tolerances of real-world environments.” Having overcome these hurdles with its technological capabilities, IdeaOcean is now conducting mechanism design projects for next-generation mobility and home robots at the request of Hyundai Motor Company and Samsung Electronics. “We aim to become the world’s leading player in intelligent automated design, responsible not only for design but also for prototype production,” Kim said.

Hur Jin-seok

AI-translated with ChatGPT. Provided as is; original Korean text prevails.

ⓒ dongA.com. All rights reserved. Reproduction, redistribution, or use for AI training prohibited.

Popular News